This article was #3 of the Top 25 most well-read articles on www.progressivedairy.com in 2013. It was published in the March 1, 2013 Extra e-newsletter. Click here for the full list of the Top 25. Pumping systems are a popular way to move liquid on dairy farms. Nancy Puck of Puck Custom Enterprises Inc. provided an overview of pump capabilities by using the pump’s performance curve.

We asked Puck,

Q. Why is it important for dairy producers to learn about pump performance?

Water and liquid manure will add up to be the largest volume of material a dairy will need to handle each year. How cost-effectively a dairy producer can move this liquid in a timely fashion will determine if the water and liquid manure are assets to the farm or liabilities.

By correctly sizing pumps and the fluid delivery system of pipes and hoses, this large volume of liquid can be transported and managed with minimal cost. However, if these systems are incorrectly sized for the farm, the farm can suffer greatly from the high costs of transporting that liquid.

By understanding pump performance curves, a dairy operator can quickly compare pumps to identify:

1. How fast can this pump move liquid? (gallons per minute)

2. How much energy will it create to overcome the losses in the fluid delivery system? (total dynamic head per psi)

3. How much horsepower is required to operate it? (fuel or energy consumption)

4. How energy-efficient is this pump?

This ability to understand pumps on a farm is as important as understanding engine performances when sizing a tractor to manage fieldwork. PD

â Nancy Puck, Puck Custom Enterprises Inc .

ARTICLE:

As we plan a pumping system to move liquid on a farm, we must know what the capabilities of our pump are, and what the friction losses in our system will be.

This is an overview of pump capabilities as detailed on the pump's performance curve.

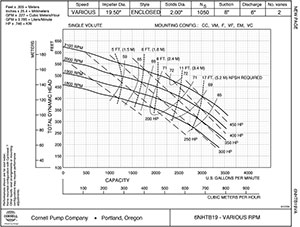

On one axis of the pump curve, you will find capacity, and on the other, total dynamic head (TDH). Capacity is measured in U.S. gallons per minute or cubic liters per hour.

This tells us what the pump is capable of flowing if we fulfill the other inputs: RPM, horsepower and NPSH required.

These inputs are detailed in Figure 1 above, as well as the pump's efficiencies. Click here or on the image at right to view it at full size in a new window.

TDH is measured in feet or meters. By dividing feet of TDH by the 2.31, we can convert feet of head to pressure as psi (100 feet / 2.31 = 43 psi).

This is useful if you know how much pressure you need, or so you can read the pump's outflow pressure gauge, and in reverse, multiply by 2.31 to estimate the feet of TDH (100 psi x 2.31 = 231 feet).

You can then better understand how the pump is performing through referencing the pump curve. Higher pressure does not equal higher flow.

Why is the measurement on the pump curve in feet or meters and not pressure? Pressure is related to the type of liquid, its specific gravity. Heaver liquids will create more resistance and therefore more pressure.

Head is a fluids term that measures the kinetic energy a pump creates. The pump will move any liquid to the same vertical height (feet) if the pump can be spun at the same rpm.

For liquids with a higher specific gravity than water, more power is required. Pump performance curves are based on clear water at sea-level.

RPM tells us how fast we are rotating the pump. Using the rpm curves, we can find how much TDH the pump will create at a given flow rate at any point on that curve.

Intersecting the rpm curves are horsepower requirements. Horsepower increases with higher flow rates and higher TDH.

Net Positive Suction Head Required (NPSHr) is the required minimum inflow to keep the pump from cavitation and allow it to work properly. This number helps us calculate how much lift a pump has on the intake side.

Pumps create a vacuum at the center of the impeller that draws fluid into the pump. After priming the pump, this vacuum continues to work if the pump is within a close enough distance to the liquid allow atmospheric pressure to fulfill NPSHr.

If not, you may need to provide inflow to ensure this requirement is filled. Cavitation creates massive damage to the pump. We will discuss NPSHr and cavitation in more depth later. PD

Nancy Puck

Puck Custom Enterprises, Inc.

(712) 653-3045