In recent years dairy farms have grown in size and efficiency. When more livestock are housed in one location, the volume of stored manure and the manure hauling distance to reach the land base needed for application also increase.

Manure agitation, pumping, transport and land application typically cost $100 to $160 per cow per year for a Michigan dairy farm. Because hauling and land application greatly impact labor needs and must align with tillage and planting plans, many farm managers are custom-hiring manure-hauling services.

We recently completed a study of labor, machinery and manure-hauling rates (gallons per hour) for custom applicators using 13 hauling systems on 10 farms in Michigan, Ohio and Ontario.

Tank spreaders and travel time

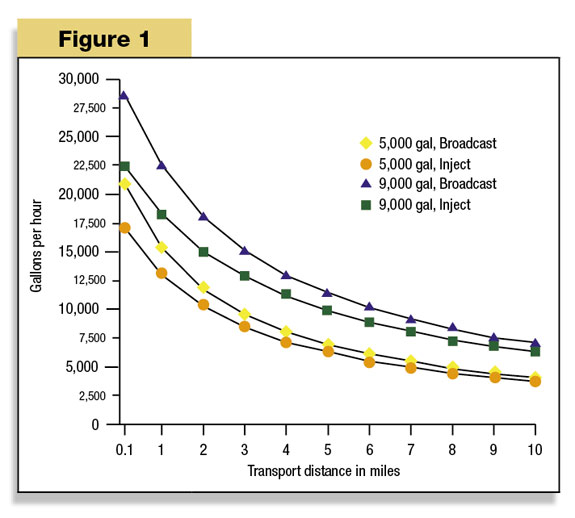

When tank spreaders were used for over-the-road transport and land application, they typically needed about 14-plus minutes travel time for each load. When hauling to fields near manure storage, applicators applied three to four loads per hour, but the hauling rate declined by 20 percent, 40 percent and 50 percent with one-mile, two-mile and three-mile hauls, respectively (Figure 1).

The most effective way to increase the hauling rate was to increase the size of the spreader tank and increase transport speed. Speed and tank volume became more important as the hauling distance increased.

For instance, increasing tank capacity 20 percent (e.g., from 7,000 to 8,400 gallons) increased hauling capacity 8 percent near the pit, 13 percent with a three-mile haul, and 15 percent with a five-mile haul.

A 20 percent increase in travel speed had little effect when hauling to fields near storage, but increased hauling capacity 8 percent with a three-mile haul and 11 percent with a five-mile haul.

Increasing the loading rate at the pit or increasing the injector flow rate by 20 percent increased hauling capacity about 4 percent when hauling near the pit, and 2 percent with a five-mile haul.

Manure-handling equipment has evolved to transporting and applying manure quickly and efficiently. Large spreader tanks, in-field holding (frac) tanks, nurse trucks with boom extensions, and high-capacity pit and spreader pumps have reduced the time needed for loading, unloading, transport and land application.

Custom applicators who we observed used tank spreaders ranging in size from 6,000 to 10,000 gallons and tractors with speeds ranging from 25 to 40 mph. Semi-tractors with nurse tanks averaged 31 mph fully loaded, and 35 mph when empty.

Flow and unloading rates

High-capacity manure pumps and pump agitators were available, but seldom used at full capacity because high flow rates can cause foaming in the spreader tank and in some cases pipe stands become unstable at high flow rates.

The greatest flow rates were used for pit agitation. A typical pumping rate for tank spreader loading at the pit was 1,900 gallons per minute (gpm).

Depending upon how the slurry was applied, spreader unloading rates ranged from about 900 to 3,000 gpm. The lower rate was with a 6-pt injector when the flow rate was controlled by a hydraulically-driven pump to achieve an agronomic rate of 7,000 gallons per acre.

The high rate was a broadcast application with a 9,500-gallon tank spreader. A typical spreading rate was 2,500 gpm for broadcast application and 225 gpm/injector shank for injection. Injection units had five or six shanks, but one custom applicator used a nine-shank injector to increase spreading capacity.

The time needed to maneuver and position tank spreaders near the pit and in the field ranged from five to 7.5 minutes when hauling over-the-road from the storage pit to the field. Maneuvering time was reduced to three to six minutes when the tank spreaders remained in the field and were serviced by nurse trucks.

Nurse trucks and truck-drawn spreaders needed more time for maneuvering and positioning in the field and at the pit, ranging from four to nine minutes per load, total.

Summary

Manure land application may be a time-consuming task that can conflict with the timeliness of spring planting or be delayed until fall field and weather conditions are suitable for application. The capacity of tank spreaders declines with increased haul distance from storage to field.

Custom applicators generally have access to large tank spreaders, high-speed tractors, in-field frac tanks, nurse tanks with boom extensions, high-capacity pit pump/agitators and other equipment, and technologies that can improve hauling efficiency and improve productivity. The use of custom hauling services may be a good business decision for many dairy producers. PD

References omitted due to space but are available upon request to editor@progressivedairy.com .

âÂÂExcerpts from Michigan Dairy Review, Vol. 16, No. 2, April 2011

-

Tim Harrigan

- Associate Professor

- Michigan State University

- Email Tim Harrigan

.jpg?t=1687979285&width=640)