As automated milking gains traction across the country, dairy producers are learning that some cows are just better suited than their herdmates to thrive in these systems. By breeding for specific robot-friendly traits, you can genetically build cows that are set up to succeed.

The cost-effectiveness of robotic milking is often expressed in pounds of milk per robot per day. The higher this number, the lower the fixed cost per pound. If automatic milking is to be successful, the farmer must spend as little time as possible rounding up (fetching) cows.

The productivity of such systems rises significantly if the animals approach the robots of their own volition. Again, this is a characteristic that can be incorporated into a successful breeding program.

The average output of U.S. farms with robotic milking systems is 4,125 pounds per single-box robot per day – though some achieve up to 5,500 pounds. Their effectiveness depends on such factors as feed, management and stall layout – but breeding also plays a major role.

Increase robot ROI by selecting the right traits

A well-thought-out breeding program can help to increase the return on investment for robotic milking systems. In fact, there are indices that make it easy for producers to breed cows that perform best with robots. In addition to external characteristics such as udder and legs, a breeding plan for robot compatibility should incorporate less immediately obvious traits, such as milk speed and character.

Incorporating genetics from sires that score well on these traits leads to more milk for the producer – and a healthier bottom line.

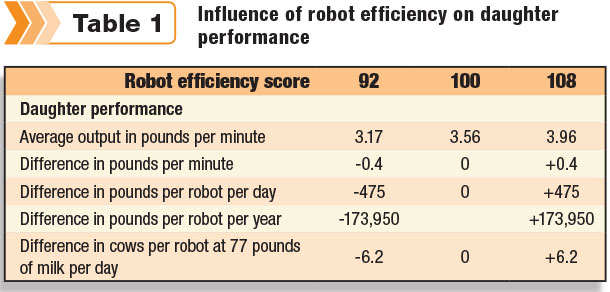

Table 1 above shows that breeding for robot efficiency increases the use of robotic milking systems. A farmer who uses only the best bulls for traits that lead to robot efficiency ultimately obtains nearly 350,000 pounds of milk more per box than one who uses bulls not suited for robots.

Another breeding value that directly affects automatically milked cows’ performance is differences in milking intervals between daughter groups. The higher the index, the more likely the bull’s daughters are to approach the robot themselves, and the less time the farmer spends supervising them. Using bulls with high milking interval scores has a direct effect on productivity.

Six key traits for robot farm breeding policy

What constitutes ideal robot cows, and how can dairy producers create them using genetics? Matthew Costello, CRV genetic product manager, has a clear vision of how farmers should breed for automated milking based on his own experience with robots on his family’s farm. He identifies the following traits:

- Udder conformation

- Legs

- Hoof health

- Output per milking

- Robot efficiency

- Robot interval

He says the first trait is udder conformation and, particularly, the position of the rear teats. If these are too close together and the udder is strongly attached, the robot has difficulty milking the cow. “Udder traits are about 30 percent inherited, and good bull selection compensates for udder problems in one to two generations.” A mating program can also be very helpful in this respect.

The effectiveness of automated milking also depends very much on whether the cows are able to walk toward the robot, which is why Costello says leg traits are an important aspect of the breeding program. He states, “The ideal robot cow walks quickly in a straight line, and its legs are neither too bent nor too straight.”

And hoof health indices should be another factor in bull selection, he adds. “Even the slightest hoof problem has a direct effect on robot usage.”

Cows with a genetic predisposition to high output per milking also help to maximize robot usage and minimize the fixed cost per pound of milk. For the same reason, Costello says robot efficiency is a useful indicator when selecting bulls. Another is robot interval: how often the cow visits the robot of her own volition.

Not every cow is suitable for robot milking

With 130 cows to be milked, Ron and Ester VanLangen’s two single-box robots are kept very busy. The cows graze day and night for a large part of the pasture season on the couple’s farm in Edgar, Wisconsin, but average 2.7 milkings per day.

“Good legs and healthy hooves are essential to our herd,” Ester says. She and her husband were among the first dairy farmers in the area to use milking robots in 2009. “We began with a couple of bought-in cows, and we soon realized that not every one was suitable for robot milking. For example, the rear teats can cause problems if they’re too close together, but we use breeding to control this trait.”

Apart from American Holsteins, the VanLangens use Holstein and crossbreed bulls from New Zealand. “It’s essential to have milk speed breeding values for these, and we take that into account when we choose them,” Ester says. “It’s also very useful to have a value for robot efficiency. Breeding for us is a very important tool in optimizing our robot management.” PD

Wichert Koopman is a journalist.

-

Matthew Costello

- Genetic Product Manager

- CRV

- Email Matthew Costello