Respiratory disease in calves continues to be an issue dairy producers across the country are dealing with. According to the National Animal Health Monitoring System (NAHMS) Dairy 2007 study, respiratory disease was the second leading cause of death in unweaned heifers and the single-largest cause of weaned heifer deaths. And, more often than not, poor ventilation is the root cause of the respiratory issue.

Poor ventilation usually means there is a build-up of bacteria in the air. High levels of bacteria can have detrimental impacts on calf health and growth potential.

Poor ventilation is typically associated with the smell of ammonia. People often recognize the smell of ammonia and assume that if they can smell ammonia, the air quality and therefore ventilation must be poor. The presence of ammonia isn’t good, but it is not the only sign of poor air quality.

If you cannot smell ammonia, you still may have air quality and ventilation problems. Simply put, bacteria do not smell. A build-up of bacteria in the air may be present without the smell of ammonia.

Even if you could go by smell, it would be hard to detect air quality because the air we breathe at our level is much different than the air two feet from the ground, where the calf sleeps. Considering calves typically spend 85 percent of their time asleep, calves can be lying down and breathing low-quality air for a long time each day.

To help dairy producers get a better handle on how air quality may impact calf health, Land O’Lakes Animal Milk Products tests air quality with a device called the airIDEAL, an instrument commonly used to monitor air quality in hospitals and cruise ships.

The device is able to read the bacteria level in the microenvironment the calf lives in, giving a representative sample of the air the calf is breathing while lying down. (At this time, benchmarks have not been established to detect the air quality for adult cows).

Although the device does not detect what types of bacteria are present, high bacteria counts are a good indicator that bacteria might be a cause of respiratory disease.

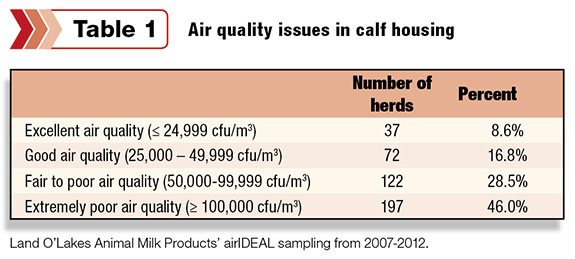

Over the past six years, the air quality has been sampled in calf housing on 428 farms in 16 different states. Air quality samples were rated as excellent, good, fair to poor or extremely poor.

Of the 428 farms evaluated, 25.5 percent of the herds had good quality air and 74.5 percent were rated as having fair to poor or extremely poor air quality in their calf housing facility (see Table 1 ).

Results from these tests underscore the need for dairy producers to focus on ventilation in their calf housing.

To improve ventilation, one option may be to have a professionally designed positive pressure tube ventilation system installed that can bring fresh air into the facility without creating a draft on the calf. This will allow the proper exchange of air to take place.

Ideally, there should be four air changes per hour in cold weather, 15 air changes per hour in mild weather and 60 air changes per hour in hot weather.

Professionally designed positive pressure tube ventilation systems can deliver fresh air at the calf level without creating drafts. Natural ventilation will not properly exchange the air at the calf level, especially when the wind isn’t blowing!

Positive tube ventilation systems must be professionally designed to ensure the quality of air. The University of Wisconsin – Madison offers training sessions to teach people how to properly install these types of ventilation systems. ( Click here for additional information on installation and training)

But just installing a positive pressure tube ventilation system won’t solve all of your ventilation problems. In fact, installing this type of system will fail to reduce the incidence of respiratory disease in roughly 25 percent of herds.

Once calf housing is properly ventilated, bacteria levels should remain low and so should the incidence of respiratory disease. But as the testing shows, 25.5 percent of the herds tested had low bacteria counts, but they still had respiratory issues. Follow-up tests may be needed on these herds, but there could be additional factors at play behind the respiratory issues.

Other issues that could be causing calf respiratory issues include:

• Outside air quality – Make sure the air being drawn into the building is fresh. If the air pulled into the building is coming from a lactating pen or manure lagoon, bacteria levels will be high, adding further bacteria into the facility. For ventilation to work properly, any added fresh air must be fresh.

• Pen size – Group housing should be sized to provide 35 to 40 square feet per calf. This space allotment allows easy maintenance of a deep, dry bedded pack, ideal calf movement, calf growth and reduces the concentration of bacteria as they are dispersed over a greater area.

• Bedding management – Keep bedding dry and provide enough bedding material that the calf can be protected from potential drafts. Make sure the pen has adequate drainage; this will assist in keeping the pen dry.

• Umbilical cord disinfection – Make sure all newborn calves’ umbilical cords are disinfected with 7 percent tincture of iodine as soon as possible after birth. Cords should be disinfected inside and out. Pathogens that cause respiratory disease can enter through the umbilical cord.

• Calf nipples – If the nipple height is too high or the opening in the nipple is too large, the calf can aspirate milk into its lungs, which can cause pneumonia in addition to bloat and digestive upset. Too often, the nipples and vent holes are open too wide.

If a calf is drinking its bottle in five minutes or less, the openings in the nipples are likely too large. Drinking milk too fast also reduces the amount of saliva produced by the calf and reduces its buffering capacity.

In addition, if a calf does not satisfy the urge to suck, it will suckle other calves or equipment. Be patient while the calves feed. This time can be used to put out fresh water and calf starter.

• Hygiene and sanitization – Cleanliness is of the utmost importance when it comes to preventing the spread of disease. Strict protocols for cleaning and sanitization should be followed routinely.

• Slow detection – Calves should be screened for respiratory disease twice a week using the University of Wisconsin – Madison screening program. This tool can assist in the early detection of respiratory disease. Click here to download a PDF of this tool.

• Nutrition – If calves do not receive enough nutrition, they will cross-suck and spread disease through the group. Calves should be fed at least 1.8 to two gallons of milk or milk replacer per day and free-choice water and calf starter. PD

Earleywine has a Ph.D. in dairy science from the University of Wisconsin – Madison and is director of nutritional services for Land O’Lakes Animal Milk Products.

References omitted due to space but are available upon request. Click here to email an editor.

Tom Earleywine

Director of Nutritional Services

Land O'Lakes Animal Milk Products