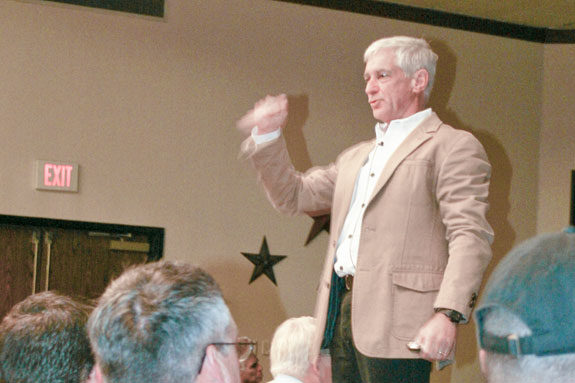

The High Plains Dairy Conference kicked off in Amarillo, Texas, at the Ambassador Hotel March 11-12. As is customary for the conference, producers took part in two days of educational presentations and networking that organizers hope will help them improve their dairies. Success through people Tom Fuhrmann talked about management systems and how to get more out of your dairy and your employees, especially Hispanic workers. He emphasized the differences between American culture and Hispanic culture and why those differences may get in the way of some of the results producers expect out of their new managers.

He said that “gringos,” for the most part, grow up in a very competitive, capitalistic culture and look for results. On the other hand, Hispanics come from a socialistic culture, “Muy Amigable,” where they all want to be friends. They don’t like confrontation.

Fuhrmann interacted with the audience quite a bit during his presentation. At one point he asked how many of them were looking for the perfect manager to walk in their door. Even if you find the perfect employee, you will have to pay dearly for them or they will be gone after a couple years anyway, to earn more money somewhere else, he said.

He suggested that owners need to recognize the “diamond in the rough” already on their dairy because it’s hard to find the perfect employee. After finding a good candidate, you must train him or her to know the dairy’s technical procedures as well as your philosophies so that when your leader needs to make a choice, he or she will be better able to take care of the situation. There was good participation from the crowd, and many ideas were shared about working with Hispanic workers.

He said, “Simply stated: Successful large dairies get results through people.”

Needle-free injections

C. Scanlon Daniels, a veterinarian with Circle H Headquarters, gave some pros and cons for the use of needle-free injections. First, he explained why the implementation of needle-free injections is not easy. The technology is different, and it’s not just changing tools, he said. He also explain that there are a variety of devices available but not all of them are created equal. The three main types of needle-free injectors are spring-loaded, battery-powered and gas-powered. The spring-loaded injectors cost less but do not penetrate the layers of tissue as deeply as the gas-powered devices. The gas-powered devices are more effective, but cost more.

The benefits of using this type of system include more efficient vaccine use (reduced vaccine costs); targeted immune response; improved carcass quality by eliminating broken needles, carcass bruising and abscesses; reduced spread of infectious diseases through needles; and improved safety for workers.

Market outlook

An enlightening economic forecast was given by Bill Cordingley of Rabobank International. Native to Australia, he said he appreciated the landscape in the conference location because it is similar to where he is from.

A couple of the take-away messages were:

• Exports are more sustainable than DEIP levels

• Exports now are a more significant share of production

• Exports now impact the U.S. milk price considerably

Though his outlook was generally positive for the future, Cordingley shared some potential risks. First, there is always the possibility for a double-dip in the recession, but he said that was not very likely. Another risk is that the Northern Hemisphere could have strong spring production and then if China had a sharp reduction in buying, the economic problems around the world could be felt for some time.

Cordingley did say that he expects demand to increase and end use will expand, but slowly. He mentioned that prices could dip again this summer, but over the next five to 10 years, there will be good growth in the world market.

Centralized calving

Attendees learned about the pros and cons of centralized calving in a presentation by John Smith from Kansas State University. He shared specific examples from a dairy in Idaho that put all of its close-up cows in one barn. The cows were then rotated to pens closer to the calving area just before they calved and kept in the barn a few weeks after calving. This system allowed workers to keep a closer eye on the cows that were just about to calve. This approach can be used between multiple farms so that this stressful time in a cow’s life can be handled by specialized employees and more efficient labor. This management system works best when servicing 8,000 to 10,000 cows, or about 25 cows calving each day.

The key pros are development of key employees with key skills in handling dry and fresh cows and calves. Also, if milk cows are relocated for calving, there is more space available for milking cows.

The most notable problem is that having all the cows and calves going through one facility increases the chance of spreading diseases. If there is a management problem, the effects will be seen in dramatic fashion.

Nature is telling us how to feed calves

Lonnie Holthaus with DeLaval talked about feeding calves the way nature always has – multiple times a day in groups. This is achieved through automatic feeders that can monitor the intake of each calf while providing food whenever they want it.

He said, “We’ve been doing it wrong so long we think it’s right.” He also cautioned, “Don’t believe everything you think.”

Some of his points were made when comparing beef calves to dairy calves; beef calves grow up in groups, eat multiple times a day and have more rapid gains. Holthaus said that more frequent feedings make three-pound gains each day possible instead of one-pound gains.

The first question that was asked by the group was about the spread of disease. Holthaus said there needs to be good ventilation and good management techniques or health problems could arise. However, he said the calves that are exposed to common pathogens in groups will be stronger animals and less stressed about group settings later on.

Using infrared on your silage

Silage and infrared technology are not always synonymous, but Brian Perkins, Diamond V Technologies, talked about using infrared imaging technologies to assess silage storage and handling. He showed multiple images of silage faces that were not kept even or packed loosely, and with the infrared camera, pointed out where the high temperatures were. He then explained what the losses were like in those piles and the losses in the milk tank from feeding that silage. For example, a 30ºF rise in temperature costs about 40 pounds of milk per cow each time the temperature rises because it burns or breaks down the sugars, starches and proteins in the ensiled forage. High temperatures also negatively affect palatability and mycotoxin populations.

He did say that the technology is expensive and that producers that are interested should look at borrowing or sharing an infrared camera. It gives a conclusive look at silage bunk management that will help explain to workers why silage needs to be packed tight and defaced evenly. Nutritionists would also find some benefit in the technology, he said. If a producer does decide to buy the infrared imaging equipment, Perkins suggests looking closely at the software. The imaging software that takes pictures as well as shows temperatures helps paint a clearer picture. PD

By Ryan Curtis