Two years ago, So-Fine Bovines in Westfield, Wisconsin, replaced Presynch/Ovsynch with automated heat detection as its primary breeding protocol. Brooks Buchholz, the dairy’s herd manager, says he likes that the new system has cut down on the number of shots he must administer.

On the other hand, he’s seen an increase in the incidence of natural reproductive challenges that the dairy’s previous hormone-based protocols masked or perhaps even prevented.

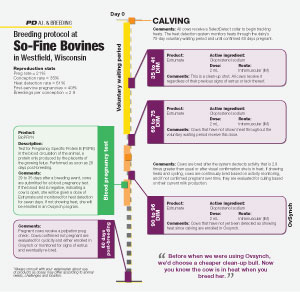

Click here or on the image at right to to view it at full size in a new window. Click here to open a pdf of this article.

From synch to automated

In May 2010, So-Fine Bovines installed SelectSire’s Select Detect automated heat detection system. Shortly after calving, each cow receives a monitoring collar containing an accelerometer. The collars collect data to build a baseline of normal activity and alert Buchholz to periods of high activity, defined as a 7-hour window during which activity is 2.9 times more than normal.

The dairy uses the collars to track activity for heat detection until confirming the cow is 60 days pregnant. Of So-Fine Bovines’ 670-cow milking herd, 320 animals are usually carrying one of the devices at any given time. On average, more than 80 percent of the dairy’s breedings rely on the automated system.

“Regardless of what the system tells me, I still walk the pens every morning,” Buchholz says.

Buchholz doesn’t have any complaints about the automated heat detection system or the technical support provided for it. He says he’s confident breeding heats caught by the system with higher-priced bull semen.

“Before, when we were using Ovsynch, we’d choose a cheaper clean-up bull,” Buchholz says. “Now you know the cow’s in heat when you breed her.”

Striving for better

Buchholz says he’s OK with the dairy’s current 21 percent pregnancy rate, but like many dairymen he wishes it was higher. He hopes to one day have 50 percent of cows pregnant on first service through the automated program, compared to the current 40 percent.

“If you have a better pregnancy program and you’re getting cows pregnant sooner you’ll be able to turn those genetic generations over a little faster,” Buchholz says about the effect his program has not only on the dairy’s profitability but also on its genetic progress.

Half of the dairy’s Holstein cows are registered and the other half participate in the Holstein Association USA’s BasicID program,which enables a producer to start officially recording ancestry for any animals that have few to no officially identified animals in their pedigree.

The BasicID cost is $1 per animal. The association’s program will allow Buchholz to upgrade animals to full herdbook status after a number of generations of his choosing, typically after three generations of sire ID.

To speed genetic progress, Buchholz and his father, Jeff, have considered the counter-intuitive: Give cows a few more days of voluntary waiting period (VWP). Three years ago, they increased it from 60 to 70 days and would consider increasing it again.

“I know some guys are out 80 to 90 days on their voluntary waiting period,” Buchholz says. “I’m not sure what the magic number is.”

Currently the Holstein cows at So-Fine Bovines are milking about 96 pounds per day from 80 to 90 days in milk during their first lactation. Later-lactation cows are over 130 pounds during the same timeframe. Buchholz attributes the fact that cows are nearing peak milk production to their lower conception rates, about 35 percent, and thus the lower annual average pregnancy rate.

Natural heat, natural problems

At any one time, a half dozen or so cows may be on Ovsynch, which is now the secondary breeding protocol for the dairy. The protocol is used for cows that: 1) do not show heat during the VWP or 2) are bred and confirmed pregnant by palpation or blood pregnancy test but thereafter suffer embryonic death loss and don’t show a promising heat cycle.

On an annual basis, early embryonic death loss occurs with about one in 15 of the dairy’s confirmed pregnancies, Buchholz says.

Buchholz says he’s been told to remove the heat detection collars after a positive blood pregnancy test. However, the dairy leaves them on until after a palpation pregnancy check so they can catch cows that suffer embryonic death loss, start cycling and show heat again shortly thereafter.

He says he hasn’t tried letting such cows go through a full heat cycle and waiting for the next one before breeding to see if conception rate improves.

Possible solutions

With some training and ultrasound on the farm, Buchholz says he believes he could catch cows suspected of early embryonic death earlier and return them into an active breeding protocol.

“I’ve wanted to get an ultrasound and just play around with it,” he says.

Having switched from Presynch/Ovsynch to heat detection, Buchholz says the dairy’s incidence of cystic cows has increased. Cows diagnosed as cystic are currently enrolled in an Ovsynch program. Buchholz says it’s working “half-way decent.” On-farm ultrasounds, he says, might also help.

“We haven’t found a magic solution for cystic cows,” Buchholz says.

After two years using the heat detection system, Buchholz is watching the collars more carefully because their batteries seem to fade after about 24 months of use.

“I check to make sure if any collar’s battery power is getting low and get those changed,” Buchholz says. “You don’t want to go three or four days without data because of a dead battery. If a cow comes in heat during those three days, that’s another 21 days you’ve missed before she’s in heat again.” PD

-

Walt Cooley

- Editor-in-chief

- Progressive Dairyman

- Email Walt Cooley