There reaches a point for many dairy producers when retrofitting existing facilities produces diminishing returns. Before 2009, the cows at Diederich Farm LLC were housed in a late-1960s-style freestall barn – low roofline, low sidewalls and short stall beds.

“At the time it was built, it was the Cadillac of cow comfort,” Daniel Diederich, fourth-generation dairy producer at the De Pere, Wisconsin, dairy, says about the old barn. “But we’ve learned a lot since then.”

When Daniel took over the day-to-day operations of the 300-cow dairy from his parents, Raymond and Debra, he took out the sidewalls of the old barn and installed some fans, but the retrofits weren’t helping with production or comfort.

There was simply no room to add to the stall size or add enough ventilation to make the barn truly comfortable for today’s larger cows.

“When my parents and I started planning to renovate, we wanted an entirely new system with three things in mind: comfort, cooling and robots,” says Daniel. “All of the systems needed to fit together, so we worked through what bedding would work best with the robots and what cooling system would work best in the new barn.”

Robots as the cornerstone

When Daniel was making career plans, he knew the only way that he was going to go back to the family dairy is if they made some changes. Some big changes.

“When my parents decided we were going to renovate, we talked about what our – and my – goals were,” he says. “We wanted a new barn, and we had to have robots. That’s the main reason I came back to the dairy. If it wasn’t robots, I was going to find something else to do.”

Robotic milking technology that helps reduce the traditionally long hours required in the parlor is something drawing the next generation of producers back to the farm.

Work-life balance is becoming more and more important, and dairies designed with labor-reducing technologies are helping make farming goals a reality for many young producers.

Additionally, reducing the need to hire outside labor helps keep costs down as well as eliminate many issues with managing employees.

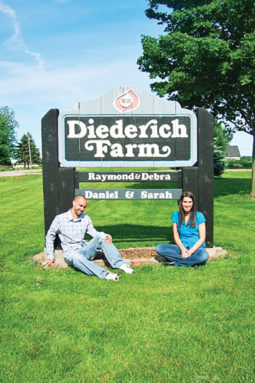

Today, Diederich Farm has four robots milking 300 cows and farms 400 acres of land. Daniel and his wife, Sarah, are the co-owners along with Raymond and Debra.

Daniel is the chief operations officer and has two full-time and two part-time employees. Sarah works some hours on the farm but recently graduated from the University of Wisconsin – Madison’s veterinary school and is quite busy with her own career.

Nice and breezy

Having terrible ventilation in the old barn, Daniel was focused on designing the new barn with ventilation in mind.

“I visited some swine housing and saw they were using cross-ventilation and didn’t know why more dairies weren’t doing it,” he says. “When we started designing our barn in 2004 and finally built it in 2009, we worked with our builder to design it to ensure we had adequate ventilation, adequate stall space and good design for the robots.”

The cross-ventilated eight-row barn has 30 55-inch, three-blade high-efficiency fans, creating a consistent eight mph breeze on hot days.

“We have great production in the summer with no production decrease,” says Daniel. “We have a lot of fresh animals in between January and March due to the expansion, so they’re peaking in the summer months and our production remains consistent.”

Daniel thought about using evaporative cooling and fogger misters.

“We looked at putting evaporative cooling and a high-pressure fogger mister in the barn, but we decided against both,” says Daniel. “First, there was too much added water usage. Second, it makes everything somewhat damp in the barn and third, the maintenance aspect of it.”

Bedding, comfort and labor

It becomes clear when talking with Daniel that reducing labor while maintaining excellent cow comfort and consistent production is very important.

The robots allow work-hour flexibility, and the cooling system is easy to operate, so it’s no surprise that he went with a low-maintenance bedding solution as well.

“We thought briefly about sand, and it was very brief,” he says. “When I ran the numbers, it wasn’t going to work for us. We would have had to haul it in, and the daily maintenance, the wear on equipment and the wear on the robots wouldn’t have made it economical.”

Then, he looked at mattresses.

“Our cows were on mattresses previously, but one of the things I didn’t like about mattresses was they get hard eventually. Year one they were OK; year three they were all right, but by year seven they were requiring a lot of maintenance and bedding,” he says. “They were difficult to clean because they would get ripples in them, and we didn’t want to continue doing maintenance and heavy bedding.”

His solution: Waterbeds.

“Water is not going to get hard. That is one of the things that excited me about the cow waterbed,” he says. “They’re as soft today as the day we installed them.”

But what about Daniel’s focus on low maintenance?

“We use a light dusting of chopped straw on top of the waterbeds each day. Literally, when we bed we use 15-gallon barrels with the tops cut off full of chopped straw and toss a handful on top of each waterbed,” he says.

The top bedding equates to approximately one-third of a pound of straw per stall per day, or 15 tons of straw per year for the 280 stalls.

“It takes hardly any time at all,” says Daniel. “In terms of comfort, we’ve been audited for animal welfare, and we scored as good or better than any sand herd. We have zero hock lesions.”

The low bedding works well with that eight mph breeze in the barn, too, preventing the bedding from blowing around.

A comfortable future

Eventually, Daniel plans to further expand the dairy, designing a cooler and more comfortable heifer facility and dry cow barn. He also has plans to install cow brushes.

“Cow brushes are high up on the list of things we want to get,” he says. “It’s harder to see them pay for themselves, but the benefits from a cow welfare point of view are enough that it’s worth it.” PD

PHOTOS

TOP RIGHT: Daniel and Sarah Diederich sit in front of the family’s farm sign.

BOTTOM RIGHT: Cows at Diederich Farm lay on waterbeds covered with a light dusting of chopped straw. Photos courtesy of Daniel Diederich.

Holly Harper

Director of Communications and West Coast Sales

Advanced Comfort Technology Inc.