Managing a milking herd is just so much more than milking a cow. That’s why the whole system around robots must be designed with care and professionality.

At 4dBarn, a Finland-based consulting company, we have been studying labor times in robotic barns since 2014. A self-paid survey has now turned into a service for farms with AMS, and we have now measured labor time consumption in 53 farms in Europe and North America. After walking behind people working in the barn during morning chores and interviewing them about management of the barn, it is clear there is a huge variation in labor consumption and lot of room for improvement in existing robot barns.

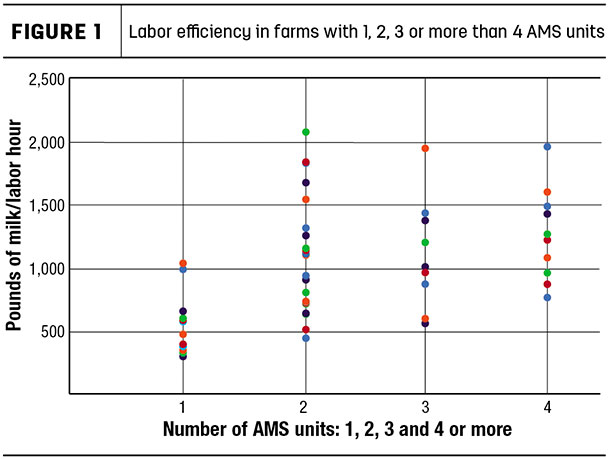

Labor efficiency can be measured in many ways. One very informative way to put labor efficiency in numbers is to divide the amount of saleable milk by labor hours used in routine, everyday work with cows and youngstock, including feeding. On our survey farms (which milked with one to eight AMS units represented by five different brands), the labor efficiency varied from 309 to 2,075 pounds per labor hour. The best farm in our survey used for daily chores a bit more than four hours to produce 8,800 pounds of milk with two robots.

How to achieve the best results

When the goal is both high milk production and labor savings, it all starts with the barn design process. It is important to take all elements of good milk production and efficient working into account and think through the whole management of the herd.

Access to basics: To promote cow comfort and health – and in that way, high daily milk yield – the basic elements are comfortable stalls with deep bedding, plenty of access to food and water, and also 3X-milking. In AMS barns, we give a cow resources she needs, and she uses them as she pleases.

Space: To make the use of those resources as easy for the cow as possible, having wide alleys and sufficient open area in front of the robots is imperative. It is not easy for a first-lactation cow to walk in the barn if alleys are crowded with standing animals, and in the robot area, she has to confront cows coming in and out of milking. Situations like that increase the chance of her being a fetch cow the next day. That, in turn, increases labor time because fetching cows is one of the most time-consuming tasks in a barn with AMS. Prolonged milking intervals also increase the risk for high somatic cell count, and fewer visits to the robot lower milk yield.

Orientation: With the right kind of robot orientation, it is possible to separate cows going to be milked from the ones exiting the robot and, in that way, make cow traffic around robots fluent. Robot orientation becomes more important when pens have two or more robots in the same area. With a wrong robot orientation, visits go down. Timid cows especially are afraid to enter the robots.

Transition cows: Research has shown transition cows benefit from extra bunk space, comfortable stalls, less competition and better supervision by herd managers. On the other hand, our experience shows that having a specific transition cow group also in AMS herds is beneficial for high production later in lactation.

Work routines: All the most important working routines should be planned already when the barn is still on the drawing table. That applies for new buildings, but is quite as important in renovation projects where parlor milking is changed into robots or an existing robot barn is expanded. When there is clear and easy routing for people and machinery, time is saved. For example, straight lines and removable gates make working with the bedding machine easier. Clean access to the AMS units, functional gating, manholes and a place to store equipment for treating cows are important to reduce steps taken. In robot barns, cows are handled individually rather than in groups. Easy and well-gated routes from all pens of the barn to the handling chute and back reduce stress for the cow and make it easy for the people.

Our data from the robot farms shows that people use an average 5.1 minutes of labor time per cow in milk. Variation is from 1.5 to almost 14 minutes. How well and efficiently you can work in your future barn is highly determined by the decisions you make in the design phase. The most vital things are to make sure you have all the elements of good cow welfare and health in your barn, and also ensure efficient labor by planning the routine work in advance.

In Figure 1, individual farms are represented as dots and arranged according to the number of AMS units.

Farms with one AMS unit are clearly not as high performing as larger farms. The biggest difference between farms is in the two AMS group. The most efficient farm gets 2,070 pounds of milk per labor hour, which is over four times more than the least efficient one. ![]()

Virpi Kurkela, DVM, is with 4dBarn.

-

Jouni Pitkäranta

- M.Sc. – Architecture

- 4dBarn