It is imperative for the success of a robotic milking operation that its cows consistently have healthy legs and hooves with minimal lameness. After all, they need to stand and move about the barn for things to work, regardless of the cow flow system in use.

In a conventional system, cows are gathered and moved to a centralized milking parlor at set times. However, in a voluntary robotic setup, the parlor is brought to the cow and she ultimately decides when to move. That freedom for the cows to choose is a primary cow comfort benefit when distinguishing robotic milking from conventional.

With that comes hoof health standard operating procedures (SOPs) that can be enhanced with the appropriate location of footbaths. The following are two examples that we as facility designers see most often.

Much on this topic has been discussed and written in the past, and the debate will not end here. It is most important to consider all the options and conditions fully in the overall context. Then, and only then, can the design team decide on the best location for each dairy.

Locations:

- In a crossover far from the robots

- In a lane after the robot

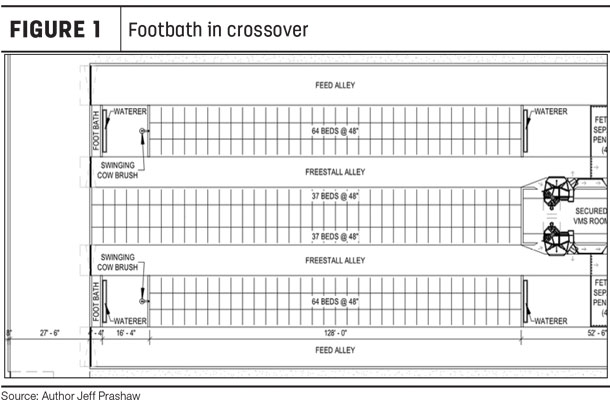

In a crossover far from the robots

This location requires cows to be manually pushed through a typically dedicated footbath lane located away from the robot(s). A benefit of this is the cows will not associate the footbath as part of the milking process. Drawbacks are it requires people to disturb the cows to push them through and it is a manual process requiring human effort. This is often the only option in a free-flow system with multiple robots in a group where there is no single lane that all cows will pass through (see Figure 1).

Click on the figures below to view them in more detail.

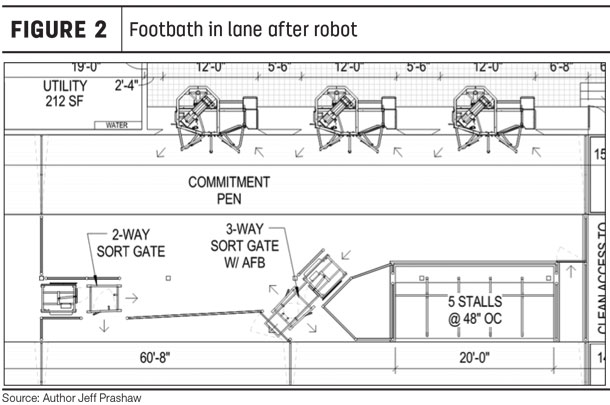

In a lane after the robot

This location requires that a footbath is placed where all or most cows pass through after milking. Indeed, the footbath is part of the milking process, but in this case, it is automated and requires only enough human effort to maintain the footbath (see Figure 2).

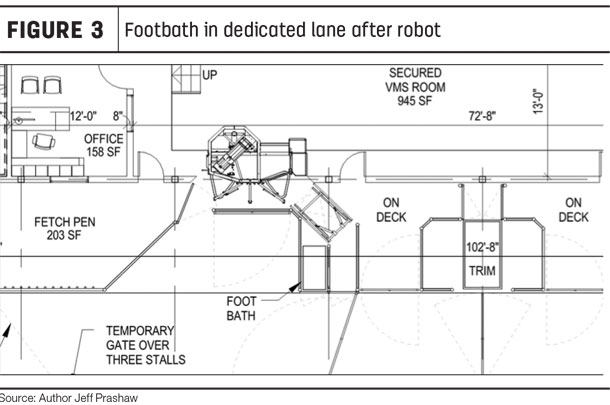

This effect can be minimized if there is a post-milking sort gate in the lane (which will be in a guided cow flow system) that can divert cows through a dedicated footbath lane (see Figure 3). This dedicated lane is only used for selected cows on any one day.

If a dedicated lane is not used, then there should always be at least plain water in the footbath to maintain consistency, as cows will become familiar with passing through the footbath. We should point out that if this non-dedicated lane approach is employed, footbath maintenance becomes extremely important as they tend to eventually fill up with manure.

Ultimately, either location can work when managed appropriately, but there are a few other considerations that we almost never see but bear mentioning. One is locating the footbath in a lane before the robot, which could lead to cows deciding not to visit the robot. You may as well place it in an exit lane instead. We do not recommend placement inside the robot, where we want extra assurance cows will not have a negative experience. This could also lead to milk quality concerns if effective hoof care chemicals are used. ![]()

-

Jeff Prashaw

- Project Design Manager – Architect MANA

- DeLaval Inc.

- Email Jeff Prashaw