Editor’s note: This is the second part of a three-part series. To read the first part of this three-part series, go to (Corn silage, feeding management, cash-flow effects) Cropping management and corn hybrid selection for silage can be major factors affecting the animal performance needed to maintain a sustainable profit margin.

In Part 1 of this series, data illustrated the variability of forage quality when hybrids were blended in the storage structure compared to feeding a single hybrid. Frequent testing of both fiber and starch digestibility is one strategy to manage the variability of corn silage.

Ration formulation can be adjusted to complement the forages but, ultimately, feeding management determines how well cows respond to their ration program. The Penn State Extension Dairy Team has been assessing management practices that affect overall farm profitability.

Dairy producers in the project were asked management questions related to ensiling and feeding. In 2013-2014 and 2014-2015, 44 and 46 producers responded, respectively.

Seventy-five to 85 percent of the producers said they fill their structures within three days of harvesting corn silage. A similar percentage indicated they monitor dry matter at ensiling.

In 2014, 60 percent said they were checking particle size at ensiling and, in 2015, 85 percent responded positively to this management practice. The project brought on 10 additional farms, and it is possible the new farms were responding favorably to that question.

A much lower number, 30 percent, were ensiling at the proper dry matter for the particular structure. This low percentage could be related to weather conditions, labor or other factors that made this management practice challenging.

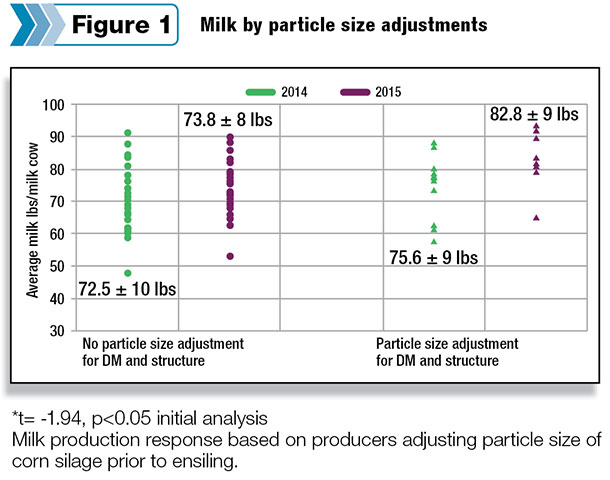

Figure 1 shows the annual average milk production using the Dairy Herd Improvement Association data, based on how producers responded to monitoring particle size pre-ensiling. The herds monitoring particle size showed significantly higher milk production compared to the herds not monitoring particle size.

Producers were also surveyed on their feeding management practices. With the same number of producers responding, 30 percent stated they did not monitor dry matter intake. The extension dairy team wanted to know how the 70 percent were determining intake. Between 50 and 55 percent use batch weights with the dry matter percent from the formulated ration.

Producers were also surveyed on their feeding management practices. With the same number of producers responding, 30 percent stated they did not monitor dry matter intake. The extension dairy team wanted to know how the 70 percent were determining intake. Between 50 and 55 percent use batch weights with the dry matter percent from the formulated ration.

Only 15 to 18 percent use batch weights and the actual dry matter percent from the TMR. Knowing the variability of forage dry matter, the formulated ration dry matters provide little more than an educated approximation to create feeding plans.

During the next phase of this project, the TMR will be analyzed; refusals and batch weights will be recorded. An accurate dry matter intake will be calculated and compared to the formulated ration.

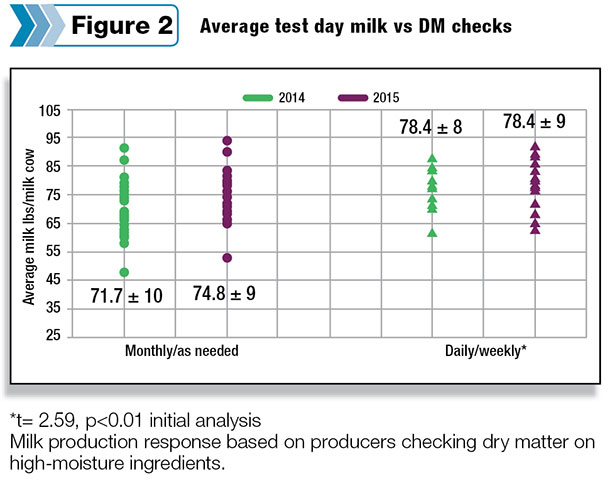

The extension dairy team also evaluated how frequently dry matter was being monitored on high-moisture ingredients. Thirty to 35 percent of producers monitor dry matter daily or weekly, with a slightly higher number (40 percent) doing it monthly or as samples are submitted for analyses.

Figure 2 illustrates the difference in annual average milk production comparing producers who test monthly/as submitted versus daily/weekly. There was a significant difference in milk production when dry matter was tested more frequently. These two practices are likely an indicator of good overall management that is contributing to higher animal performance.

During both years, in addition to sampling corn silage, milk was tested for milk urea nitrogen (MUN) and manure for fecal starch. This was a means to capture in black and white how the herds were performing based on forage quality and the formulated rations. The ideal standard for MUN is 8 to 12 mg per dl and fecal starch less than 3 percent on a dry matter basis.

During both years, in addition to sampling corn silage, milk was tested for milk urea nitrogen (MUN) and manure for fecal starch. This was a means to capture in black and white how the herds were performing based on forage quality and the formulated rations. The ideal standard for MUN is 8 to 12 mg per dl and fecal starch less than 3 percent on a dry matter basis.

Samples were taken at the same time as the corn silage in the fall and spring of both years (2014 and 2015). The average across all herds for MUN was 11.7 mg per dl and fecal starch 3.4 percent on a dry matter basis.

There were a few outliers, but the herds as a whole were consistent in their results from year to year. This illustrated the rations being fed were on target for protein and carbohydrate nutrition, and the production responses were a true reflection of management practices.

Another area the team investigated was the amount of corn silage dry matter fed and if there were any commonalities related to the feed ingredients being used to complement those diets.

There was an equal distribution between farms that fed greater than or less than 19 pounds of corn silage dry matter. Herds feeding high-corn-silage diets tended to feed high levels of small-grain silage, dry corn grain and liquid sugar. The low-corn-silage herds fed higher levels of alfalfa or grass forage and high-moisture corn grain.

The last part in this series will examine how hybrid selection, corn silage quality and cropping and feeding management influence the farm’s profit margin. The objective is to find any common practices or strategies that favor an operation being more sustainable compared to others.

This project had the advantage of capturing information in an average milk price year (2013), a spectacular year (2014) and a depressed year (2015). Evaluating one year’s financial data can be very misleading, so this study spanned multiple years to get a more accurate assessment of financial performance over time. PD

Rob Goodling Jr., Timothy Beck and Heather Weeks are also with the Penn State Extension Dairy Team.

-

Virginia Ishler

- Extension Specialist

- Penn State University Extension Dairy Team

- Email Virginia Ishler