Legendary commentator Paul Harvey always ended his daily lunchtime radio broadcasts with the affirmation, “Now you know the rest of the story.” I’m not so sure we’ll ever know the “rest of the story” when it comes to all the factors affecting total tract starch digestibility. In a previous issue of Progressive Dairyman this past spring, I explored the influence of corn silage processing on the resulting fecal starch.

Processing certainly plays a role, but a survey conducted by our nutritionists continues to shed light on what goes in to optimizing starch digestibility and reducing the amount of undigested starch that passes out the south end of a northbound dairy cow.

With corn futures dancing around the $7 level or higher, efficiently feeding and utilizing starch has been a hot topic. In the past, with cheap corn, producers didn’t worry so much about feeding a little extra.

But today, an extra 5 or 10 percent fecal starch passing through an animal can have a huge financial impact. We’d like to see less than 5 percent fecal starch in a sample and preferably less than 3 percent. But a significant number of test results are coming back well over that level.

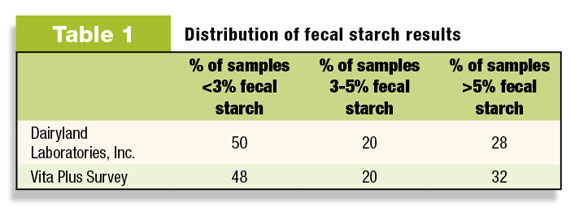

Dave Taysom, from Dairyland Labs in Arcadia, Wisconsin, summarized 16 months of results from their lab that showed almost one-third of all samples higher than 5 percent fecal starch. Our own survey showed similar results with 32 percent of all samples higher than 5 percent fecal starch content.

The good news is that around 70 percent of the samples came in under 5 percent starch, and a good share of those were under 3 percent. (See Table 1 .)

Earlier, I focused on corn silage processing and its influence on fecal starch. This article will look at some of the other factors that affect fecal starch and will use our survey results from more than 70 dairy herds to note some interesting trends.

Corn silage processing still a factor

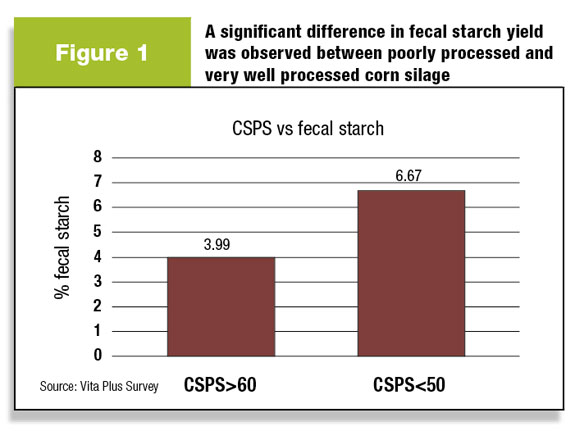

When corn silage processing scores and corresponding fecal starch levels are compared, we do see a definite trend toward lower fecal starch with higher processing scores, though when looking simply at average scores and average fecal starch, the differences are rather subtle.

Results under 50 for a corn silage processing score (CSPS) are considered underprocessed; scores of 50 to 70 are adequately processed; and over 70 are optimally processed.

Corn silage processing scores on silage fed to herds that showed high fecal starch (over 5 percent) averaged 56 CSPS. Herds with low fecal starch (5 percent or less) averaged 59 CSPS. Not a very convincing testimonial for improving CSPS.

However, when we look at the best and worst processing scores, we see a considerable difference in the resulting fecal starch.

Herds fed corn silage with scores greater than 60 CSPS averaged 3.99 percent fecal starch, while herds fed corn silage under 50 CSPS averaged 6.67 percent fecal starch.Now we’re talking significant differences in predicted milk yield.

According to Dr. Jim Ferguson of the University of Pennsylvania School of Veterinary Medicine, who is one of the country’s leading researchers on starch digestibility, a 1 percent change in fecal starch content equates to .72 pounds of milk yield.

Therefore, producers in this survey with a CSPS higher than 60 can expect about 2 pounds more milk compared to producers with inadequately processed corn silage.

Okay, theoretically that’s 2 pounds more milk … but what about in the real world? Earlier this spring, Ferguson observed dairy producers in Pennsylvania who processed in the field but did an inadequate job.

When it came time to feed this material, production suffered, so they re-processed the silage coming out of the trench, obviously a very tedious task.

“In just about every case, milk response has been 3 to 8 pounds and a reduction in fecal starch. In addition, some of the herds have reduced corn and maintained milk,” Ferguson comments.

One of the leading causes of poor processing seems to be a rush to harvest. “In some cases, the speed of harvest overwhelms the rollers and they cannot remain closed,” Ferguson concludes.

Corn silage moisture a huge factor

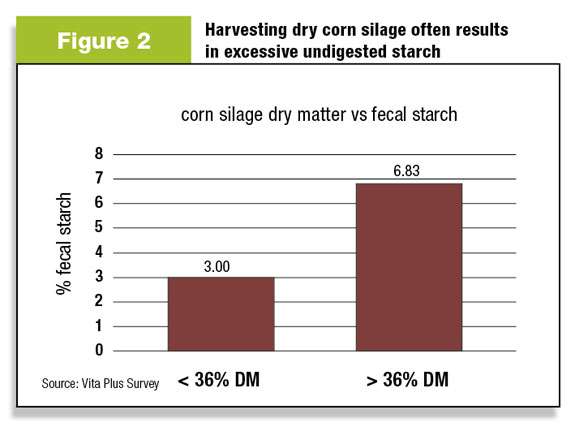

It’s been repeated numerous times at dairy seminars and meetings that corn silage moisture is one of the most important factors affecting starch digestibility. This survey bears that out very clearly.

The survey bridged the two crop years of corn silage produced in 2009 and 2010. It was interesting because, in most cases, the 2009 corn silage was significantly wetter and not as mature due to the growing season.

Corn silage from 2010 tended to be a little drier and higher in starch because maturity was easily reached. The average dry matter for all 70-plus silage samples was just under 36 percent.

Breaking out all samples with dry matter lower than 36 percent yielded fecal results of 3.0 percent, while drier samples over 36 percent dry matter averaged 6.83 percent fecal starch.

Again, applying Ferguson’s formula for milk yield, wetter corn silage and the resulting lower fecal starch would mean 2.75 pounds more milk.

Corn silage starch content

During this survey, data was collected regarding the starch content of the tested corn silages. Average starch content was 33.0 percent. Looking at fecal starch from silages higher or lower than average showed very little difference, though there was some.

Fecal starch results from corn silage higher than 33 percent starch averaged 3.53 percent. Lower starch corn silage averaged 2.62 percent fecal starch – a very small difference. Because the levels of corn silage fed to the herds in this survey varied widely, this data is probably not very meaningful. But what about ration starch?

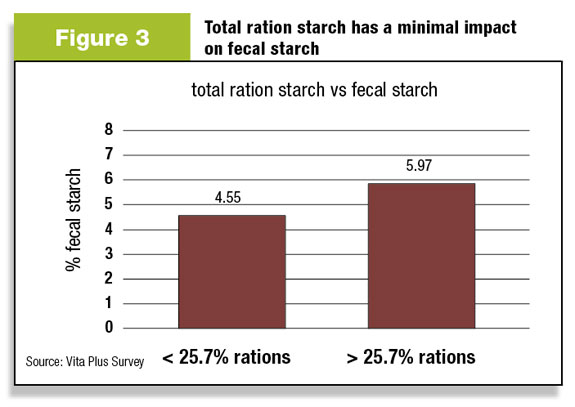

Is ration starch a factor?

Based on 778 observations on 98 dairy herds, Ferguson contends there is little correlation between the amount of starch in the TMR and fecal starch.

Our survey, based on fewer observations, would generally agree, but varied slightly from Ferguson’s findings.

The average ration starch in our survey was 25.7 percent. In the herds where ration starch data was collected, fecal starch from rations higher than 25.7 percent starch resulted in 5.97 percent fecal starch. Lower starch rations showed 4.55 percent fecal starch.

It may seem counterintuitive that there isn’t a clearer trend. However, Ferguson explains it this way, “Our correlation with dietary starch and fecal starch was low. There was a small association … but it was weak so I tend to ignore it."

"I think the data suggests cows use starch well if it is processed appropriately. There is a trend with higher milk production that all dietary inputs are digested slightly less, probably from higher DMI and faster passage.It makes one think that, as production increases, we need more rapidly available digestible NDF and starch sources.”

Time in storage … the big one

We’ve all heard it recommended that corn silage should sit in the bunker for a couple weeks, a month or whatever, in order to give it time to ferment and improve its digestibility. How does four to five months sound?

According to the results of this survey and other evidence from analytical laboratories, corn silage does not reach maximum starch digestibility until after at least four months in storage.

Cumberland Valley Analytical Services has published a graph that clearly shows a significant reduction in starch availability from samples that come into their lab beginning in September.

Starch digestibility bottoms out in November and doesn’t fully recover until the end of February.Our survey gives credence to those findings as well.

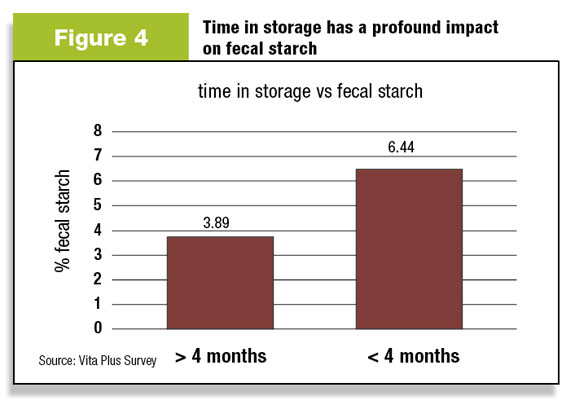

Based on 71 fecal samples from herds in almost every major dairy-producing region in the country, including Wisconsin, Iowa, Pennsylvania, New York, Texas, California, Colorado and Washington, undigested starch was almost twice as high for herds fed corn silage stored less than four months compared to corn silage stored more than four months.

Sixteen herds fed corn silage in storage less than four months averaged 6.44 percent fecal starch.

In contrast, 55 herds fed corn silage in storage more than four months showed 3.89 percent fecal starch. Once again, almost 2 pounds of milk yield difference when Ferguson’s formula is applied.

It was once thought that corn silage needed to remain in storage for an extended amount of time to allow for complete fermentation. Not so. A good fermentation is pretty well complete in a week or two.

Instead, research at the University of Wisconsin – Madison conducted by Pat Hoffman and Randy Shaver, suggests that the real culprit seems to be the protective layer of protein that encapsulates the starch layer in a kernel of corn, commonly known as the prolamin layer.

Moisture and processing have a major influence on breaking up this protective layer, but in addition, bacteria need to penetrate the coating that surrounds the starch granule. Much of this occurs in the rumen once the corn silage is fed, but the process starts in the bunker or silo as various bacteria and acids work to “soften” this protective protein matrix. And in this case, the more time the better.

Conclusions

The factors affecting total tract starch digestion are many and dynamic. Even factors such as corn silage and grain varietal differences, which were not explored in this survey, may influence starch digestibility.

Because these factors are so varied and dynamic, it is difficult, if not impossible, from on-farm observations, to isolate a single variable and measure its impact. However, the data from this uncontrolled study do suggest that producers can stack the deck in their favor by harvesting corn silage at the right moisture, shooting for a processing score of 60 or higher and striving to maintain a corn silage supply carryover of four months or longer.

In addition, using fecal starch evaluation as a diagnostic tool can be a very cost-effective way to identify production bottlenecks in relation to total tract starch digestibility. The analysis costs less than $20 and is available through a number of diagnostic labs. Run the analysis and then do a little detective work.

Dairyland Labs recommends that if fecal starch is less than 3 percent, no further investigation is needed. If the result is 3 percent to 5 percent fecal starch, the apparent total tract starch digestibility is probably over 90 percent and you’re in pretty good shape.

But if fecal starch is over 5 percent, individual feedstuffs should be evaluated.

Finally, fecal starch analysis may not lead us to “the rest of the story,” but it does add a chapter or two of useful information for making forage management and dairy ration decisions. PD

-

Jon Urness

- Nutritionist

- Vita Plus Corp.

- Email Jon Urness