Germany hosted the 2018 conference, which was well attended with over 350 participants from 34 different countries. This article will summarize some of the main topics presented and discussed at the XVIII ISC.

The ensiling process – new surprises?

In a simplistic view, the ensiling process is the conversion of simple sugars to organic acids under anaerobic conditions. However, what is known about this metabolic route is probably just the beginning.

As we know, silage fermentation is a natural process and thus can be quite uncontrolled and unpredictable. Additionally, a wide variety of factors can impact the final silage characteristics, from the conditions of how the crop is grown in the field to feedout management.

A popular and common strategy to favourably dominate silage fermentation is to use a microbial inoculant. At the ISC, there were a number of presentations about the positive effects of inoculants on the silage quality or at specific parts of the ensiling process.

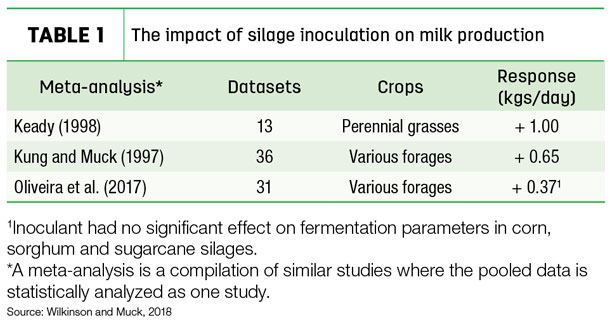

Three different meta-analyses presented showed microbial inoculation led to increases in milk production of dairy cows, even though some of the studies had fermentation/nutrient parameters that did not differ between untreated and treated silages (Table 1).

Inoculation should result in improvements in feed quality (better dry matter recovery, lower protein breakdown and high digestibility), but it may even have a beneficial probiotic effect for the animal (greater ruminal microbial biomass and reduced methane loss).

Next-generation inoculants included new bacterial species for aerobic stability (Lactobacillus hilgardii, L. diolirovans) and a bacterium-plus-enzyme combination for high-moisture hay, which resulted in higher leaf retention, greater feed value and yield.

There were presentations about micro-organisms that pose hazards to animal and human health and food safety, such as clostridia, listeria, enterobacteria and fungi.

More research is needed to improve silage hygiene and to better understand how animals are affected and the interactions between animal and silage in the field.

Molecular techniques and ‘-omics’

The development of culture-independent techniques based on the analysis of nucleic acids in silage research has increased dramatically, especially when comparing the number of abstracts submitted to this conference versus the 2015 conference.

Discussions from the essential questions in silage microbiology and biochemistry, like “What microbial species and strains?” “When and how?” and “What sort of interactions and dynamics are present or have an effect?” can now be better explained and further researched.

Using these new laboratory techniques, several presentations during ISC could now link the shifts in microbial populations with length of silage storage or stage of fermentation, as well as the positive effect of a microbial inoculation on differing forage crops.

For instance, several abstracts showed after inoculating with L. buchneri, a proven lactic acid bacterium which extends aerobic stability, the populations of spoilage yeasts and enterobacteria were lowered, the total population of lactic acid bacteria was higher, and a more consistent microbial community was present, especially when compared to the control treatment – in addition to the positive response in fermentation pattern.

Don’t forget the basics

In order to effectively benefit from the latest in silage management and preservation technologies, producers and nutritionists need to remember to start this process properly; adequate, representative and repeated silage sampling is crucial.

It was reported sampling error is the biggest source of variation in a silo and the resulting analysis.

Sub-samples should be collected from multiple loader buckets before being incorporated to the other ration components in the mixer wagon; then the sub-samples should be mixed together and, finally, a composite sample taken.

This process should be done frequently throughout the year.

Silage safety has also been a consistent topic of discussion during the past couple of ISC events. Continual research is needed to find a safe on-farm methodology to measure packing density and fermentation/storage losses.

A Chinese and German joint research team shared promising results that used a penetrometer on a skid steer with an integrated thermocouple sensor, which safely measured packing density and aerobic deterioration during feedout.

Greenhouse gases emissions

There has been increased interest to understand the processes of greenhouse gases (GHG) emissions in agriculture and silage making and to better manage and educate the population about the link between GHG and global warming.

There is still a lack of data on silage volatile organic compounds (VOC) production, which could contribute to the formation of ozone, the main culprit of poor air quality.

The VOC are rapidly formed during active fermentation or early ensiling and only lost during silage feedout.

Alcohols (ethanol) have been considered the highest contributing group for VOC emissions, but the number of compounds that can be analyzed is rapidly increasing – a metabolome analysis from German researchers revealed more than 6,000 metabolites in alfalfa silages that differed between silage that was “preferred” and “avoided” by small ruminants.

The new “-omic” analytical techniques are helping provide new insights on GHG emissions, including the mode of action in ruminants and even the impact of ingested VOC on the taste and smell of the milk produced.

Future: Self-driving/robotic systems

Driverless vehicles on the farm are a reality, and soon it will be an option for silage making (Figure 1).

The technology is already in advance stages of development, and specific silage applications could be harvesting, transporting, and spreading and packing the pile or bunker.

Drones, satellite information and integration with wireless technologies and data transfer are coming faster than ever. The utilization of these technologies will have huge impacts on personnel safety and ensiling efficiency and economy.

For additional cutting-edge technologies and new data in the silage-making industry, join me at the next ISC in China. ![]()

Renato Schmidt has a Ph.D. in animal nutrition from University of Delaware and is employed by Lallemand Animal Nutrition, North America as a forage products specialist. Bob Charley is employed by Lallemand Animal Nutrition, North America as a forage products manager and has a Ph.D. in applied microbiology from the University of Strathclyde in Glasgow, Scotland.

-

Renato J. Schmidt

- Forage Products Specialist

- Lallemand Animal Nutrition, North America

- Email Renato J. Schmidt