In mid-August, we held a teaching seminar for our software users in Denver, Colorado. This session was focused on the more experienced nutritionist, one familiar with the AMTS program and comfortable with the model and biology behind it.

We wanted to provide an opportunity to dig into some of the finer details of the program’s recipe formulation and provide insight into the biology and equations generating performance predictions.

In past meetings with the attendance of larger groups and more varying skill sets, this kind of in-depth exchange of ideas was hard to implement. However, these users were looking for an opportunity for more advanced information.

We began the program with an overview of new features in the cattle program. This past year, we’ve made changes to the program to improve ease of use, to allow quick visualizations of feed nutrient contribution and to permit user customization.

Some key areas of change this year were:

• Appending signatures to reports

• Adding a lactating beef cow milk production prediction

• The ability to turn auto-save feature of file management on or off, allowing user great file control

• The ability to show or hide feed cost on reports

• The ability to show or hide feed cost on reports

• A cloud-based add-on allowing formulation using smart devices

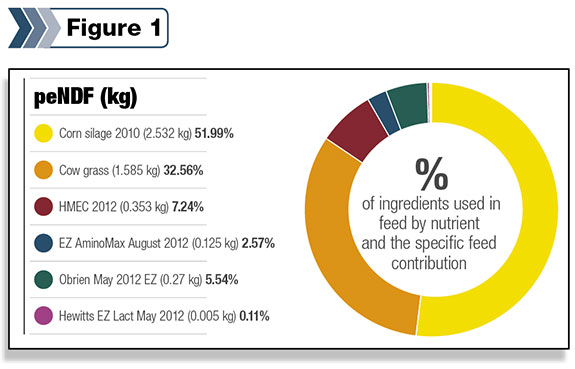

• Tables and graphs showing, by nutrient, specific feed contribution (See Figure 1 )

Tom Tylutki, a contributing model developer and practicing nutritionist, explained how the model translates science-based inputs into bottom-line efficiencies and profitability.

After covering specifics of the program features, we expanded our focus to changes that can be expected in the near future – both from the AMTS program standpoint and in the CNCPS model.

Coming updates will incorporate an administrative feature that will allow companies to set access within company files, a feature that will give users the ability to make economic projections for growing animals. Other updates will make more nutrients available for ration inclusion.

Guest speaker Ryan Higgs of Cornell University gave insight on future CNCPS features that will further refine the model equations, allowing for protozoan inclusion and accounting for endogenous nitrogen, including a three-pool NDF, as well as incorporating animal behavior into the model.

As research gets closer to actually knowing what goes on in the “black box” of the animal, the nutritionist’s challenge will be to utilize that knowledge in ways that create healthier, more efficient, more profitable animals while increasingly minimizing the effect animal agriculture has on the planet.

The understanding of how the cow works is a work in progress. Many still think in terms of protein, energy, fiber, fats, and minerals and vitamins; the cow’s performance is based on the metabolic functions these parameters support.

The cow is interested in amino acids, lactose precursors, fatty acid precursors, immune system support, and enzyme and hormone activators. The model is steadily working toward an understanding of the dynamics of metabolism so that they can be optimized for best results.

In the past, safety factors were built in to formulation. By nature, allowing for a margin of error is more costly than hitting requirements spot on.

The cost is reflected in higher-than-necessary feed costs, increased health costs and excess nutrients being pushed back out into the environment in excrement and through respiration.

Tylutki spoke of compelling data showing reduced N outputs measured in fecal N, urinary N and reduced MUNs through careful coordination of nitrogen and energy sources and better understanding of solubilities and rates of passage.

When all of the biological updates are integrated, the overall accuracy of the model has been improved. AMTS users report that they can routinely model diets to within 1 pound of milk.

This matches evaluation data from Cornell that shows a mean prediction bias of less than 1 percent. Furthermore, the overall crude protein levels of diets can be decreased.

The current biological model has removed considerable prediction error. This means if the model predicts 68 pounds of milk, the animal will maybe produce 67 to 69 pounds. It is the “maybe” where our training and consulting becomes critical.

Our software functionality testing ensures minimal programming bugs, and new biology testing allows AMTS to explain it to users to ensure their success. Successful implementation comes down to three basic areas:

• The nutritionist fully understands how the model works.

• Appropriate feed analysis is done frequently and correctly.

• The correct data is available on-farm.

Jim Drackley of the University of Illinois presented his current information regarding calf-feeding management and information on dry-cow diets. His talk also generated a considerable amount of discussion about what the field nutritionists in attendance were finding to be successful in their programs.

During the training, nutritionists started thinking not about ingredients but rather what end-products the ingredients are supplying.

For example, ground corn is viewed by many as an energy source. However, depending on hybrid and processing, the site of digestion can be varied.

As more starch (remember, corn is typically about 70 percent starch) is degraded in the rumen, higher microbial protein flows result.

Thus, the corn ends up being a metabolizable protein source to the cow (via microbial growth). As less starch is degraded, intestinal absorption as glucose goes up. But this glucose typically does not result in milk; rather it ends up being used by organs and even deposited as fat.

A key area our recent training related to was how to maximize fermentable carbohydrate intake by the cow. This affects glucose supply to the mammary gland, amino-acid supply and overall cow health.

Then selecting the correct amino-acid pattern via feed supplementation (RUP sources), the impact of fat, and minerals and vitamins are discussed.

This level of training is not a one-time installment. In Denver, there was a good deal of question-and-answer opportunities for workshop participants to discuss their tips and challenges.

Conclusion

Nutrition and farm management continue to evolve. Models and software are mere tools allowing the nutritionist and producer to make informed decisions.

Capturing that knowledge and understanding that evolution allows us to offer continuous education to nutritionists and producers via software, training and consulting. PD

Agricultural Modeling and Training Systems LLC (AMTS), based in Lansing, New York, was founded in 2005 by Thomas Tylutki, Ph.D.; Vajesh Durbal; and Caroline Rasmussen, a team that was part of a larger group at Cornell University from the early 1990s through 2005 responsible for developing (including animal research) and supporting the Cornell Net Carbohydrate and Protein System (CNCPS).