Among the most critical nutritional tools available to today’s modern dairies are those products that enhance rumen function and efficiency. These products, commonly referred to as rumen enhancers, increase the rumen’s efficiency by creating an environment that allows for the more complete digestion of ration feedstuffs. A resulting increase in the absorption of nutrients occurs.

By augmenting rumen efficiency, producers derive more value from their feedstuffs, even when dry matter intake remains the same. These enhancement products create rumen conditions that enable microbial populations to flourish.

Their modes of action include pH control, competitive exclusion, supplying the essential micronutrients required by rumen microbes and increasing fiber digestion. As these components work together, they allow more nutrients – proteins, carbohydrates, fats, vitamins and minerals – to become readily available for microbial use and direct absorption.

The rate of rumen fermentation increases, along with rumen efficiency, as rumen microbial populations thrive. For example, more glucose is liberated from fibrous feeds that contain highly indigestible carbohydrates such as celluloses and hemicelluloses.

This increased supply of nutrients to the microbes generates more energy in the form of volatile fatty acids (VFA) and more available metabolizable protein to the cow.

Synergistic

Traditionally, single-component products such as live yeasts, yeast culture, live bacterial cultures and exogenous enzymes have been utilized by the dairy industry. Recently, nutritionists have been favoring multi-component blends of these products.

This allows producers to capitalize on the synergistic benefits realized by feeding a complete package in which each product augments the rumen environment to maximize the rumen condition and fermentation.

Live yeast’s primary mode of action is to assist in stabilizing rumen pH. When the live yeast ferments in the rumen’s anaerobic setting, it does not produce the hydrogen ions that would normally reduce rumen pH when present and contribute to rumen acidity. Bacteria populations that reduce lactate levels are nurtured, which helps avoid rumen acidity and acidosis.

Yeast culture provides isoacids and other fermentation metabolites. The isoacids, or branch chain amino acids, are used by fiber-digesting microbes to produce proteins. In addition, a variety of yeast culture metabolic byproducts such as vitamins, enzymes and co-factors work to further stimulate rumen microbial protein production.

Live bacterial cultures or direct-fed microbials (DFMs) attach to the rumen wall itself. Their presence prevents pathogenic bacteria from likewise attaching to sites on the rumen wall.

Populating the rumen with beneficial bacteria helps inhibit the establishment of bad or pathogenic bacteria such as E. coli and salmonella. The beneficial bacteria also become a source of enzymes, vitamins and nutrients for rumen microbes.

Exogenous enzymes degrade complex carbohydrates, such as starch and fiber, into simple sugars, which are more easily digested by rumen microbes. As a result, the enzymes increase the nutrient supply to the cow and decrease the amount of whole grains and fiber in the manure.

Commercial enzymes are effective in a wider pH range than natural enzymes. Therefore, they assist cows during times of grain overload and lowered ruminal pH.

The trend toward using multi-component products is becoming well established among progressive dairy nutritionists. The multi-component rumen efficiency products provide value by incorporating the beneficial attributes of multiple ingredients to the rumen environment.

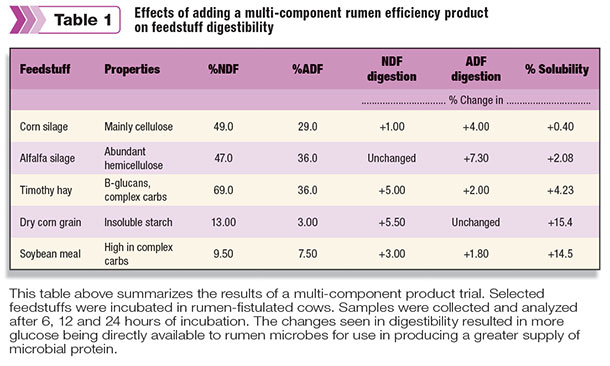

As seen in Table 1 , these components work in concert with each other, maximizing the nutrient value of feedstuffs and providing a solid return on investment.

Economics

Research has shown that dairy cows fed single-component products will typically experience an increase in milk production of approximately 2 pounds per head per day. Feeding a multi-component product, similar to the one shown in the table, can increase milk production in the range of 3 to 4.5 pounds per cow per day.

The cost to feed multi-component products can be two or three times more than the cost to feed single-component products ($0.05 versus $0.10 to $0.15 cents per head per day). However, the value of the additional milk volume and components produced far outweigh this additional cost.

With the current mailbox price averaging approximately $20 per hundredweight, a multi-component product costing $0.125 per head per day to feed can give a producer $0.70 worth of additional revenue per cow per day.

This equates to a net revenue of $0.575 per cow per day or a 5.5-to-one return on investment. This increase in income adds up over a year’s time. A 500-cow operation could see extra milk income of more than $90,000 per year.

Single-component products, such as live yeast and yeast culture, have been extensively tested and successfully fed for many years.

Now producers and nutritionists can choose from among the number of multi-component products on the market that are proving to be even more effective than their predecessors. Bottom line: the cow gets more from the ration and the producer sees more milk in the tank. PD

Bob Patterson

Director of Ruminant Nutrition

Papillon Agricultural Co.