As the 2014 silage season approaches, producers will be turning their thoughts to making sure everything is prepped and ready for the annual battle to ensure sufficient top-quality preserved feeds are available to maximize profitability. While many producers may have already been locked in to their forage inoculant during winter seed sales campaigns, there are also many who are still weighing their options, considering whether to use a different microbial inoculant on hay silage versus corn silage.

This can be a difficult question to resolve; you may get information from some sources saying that inoculants must be crop-specific, while other sources say it isn’t necessary. So, herein we hope to give you some basic pointers to help you better make your inoculant choices and also produce top-quality preserved feeds this coming season.

Rule 1: The basics never change

The goal of ensiling forage crops is to preserve as much dry matter (DM) and nutrients as possible, from the field right through to the feedbunk.

The use of a proven microbial inoculant in this process is a relatively inexpensive and safe investment, but it is by no means a substitute for good management. Remember, the major factor determining the quality of the preserved feed is the quality of the crop going in.

First and foremost, the crop needs to be harvested at the right stage of maturity and DM content. For corn, these two parameters occur at the same time: Between 32 to 38 percent DM, the plant presents good nutrient value – including starch content and sugars to drive the ensiling fermentation – while the moisture content is still high enough to facilitate good packing and promote fast fermentation.

On the other hand, grasses and legumes must be mowed before they reach their reproductive stages of maturity (flowering or seed formation, depending on the crop), or there will be a considerable decline in nutrient value, even though the yield will be greater.

At this stage, the plant is young and juicy, so it needs to be wilted until the appropriate DM level for ensiling: 32 to 35 percent DM or higher.

Ensiling crops too wet leads to a prolonged fermentation because more acid will need to be produced by the bacteria to pickle the forage mass. This can lead to higher fermentation losses and possibly feeding issues due to high total acid load of the silage. High moisture levels can also lead to excessive runoff and increase the potential for a clostridial (butyric) fermentation.

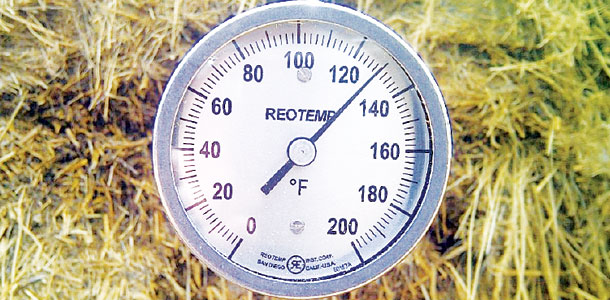

Forages ensiled too dry are harder to pack and may be prone to aerobic instability, characterized by heating and mold spoilage at feedout.

After harvesting the forage at adequate stage of maturity and ideal DM level, treated with a proven inoculant, make sure to pack tightly, cover fast and seal all the exposed surfaces; the crop will then be preserved by the lack of oxygen and the acidic environment.

So, what type of inoculant do I use?

You may not realize it, but the production of top-quality silage involves winning a war that is going on at a microscopic level between “armies” of microbes, good and bad.

Microbial inoculants have been used for many years, in basic principle loading up the army of good, or beneficial bacteria, usually lactic acid bacteria (LAB), in the freshly chopped forage. This helps win the “microbial war” and provides a more efficient ensiling fermentation and enhances its stability when exposed to air.

So our inoculant army is faced with these two fundamental challenges, which vary depending on the crop being ensiled, and local conditions, practices and history. So, crop specificity or not? Well, first let’s take a look at how we can win the battles involved in dealing with those two challenges.

How to win the ensiling fermentation battle

This is all about making sure we achieve a fast fermentation, bringing the pH down as quickly as possible, maximizing DM and nutrient retention and minimizing the risk of spoilage (mainly clostridial/butyric) fermentations.

Along with tackling the management issues we briefly reviewed above, using a microbial inoculant proven in independent trials to deliver a fast, efficient fermentation should definitely provide a worthwhile return on investment.

In the anaerobic silage environment, homolactic LAB such as Pediococcus pentosaceus, P. acidilactici and Lactobacillus plantarum convert sugars like glucose and fructose very efficiently to lactic acid only, with no wasteful side products.

Using scientifically selected strains of homolactic LAB can therefore help ensure a faster and more efficient ensiling fermentation, especially if linked to quality-controlled levels of enzymes to produce sugars to drive the acid production. The recognized effective application rate for proven inoculants containing homolactic LAB is 100,000 colony-forming units (CFU) per gram of forage.

Independently proven homolactic inoculants are recommended in all situations where there are no issues with feed stability and bunk life; you can always save on DM/nutrient retention.

Wet hay crops (less than 32 percent DM) should always be inoculated with a proven inoculant containing homolactic LAB because low-DM, high-protein haylages present challenging conditions that can easily lead to growth of clostridia, with associated protein degradation and butyric acid production, resulting in material that can be risky to feed.

Winning the aerobic stability battle

First, we need to establish if there is a need. Proven products that will reliably prevent aerobic spoilage tend to be more expensive than homolactic inoculants – and there is certainly no need to pay if there is no need. Is there a history of silage or TMR heating in the specific operation?

Is the material to be ensiled likely to be more prone to aerobic spoilage: e.g., more mature crops with high levels of fermentable carbohydrates; higher DM (more difficult to pack); field damage due to insects, hail or frost; (fungal) disease in the field; drought stress; flood exposure; slow feedout rates; silage relocation (e.g., from bag to tower), etc.?

If yes to any of these, then we need to consider products containing actives proven to improve aerobic stability.

Almost all silage aerobic instability events are started by the growth of yeasts, causing the silage to heat and then promoting more gross spoilage with the invasion of spoilage molds and bacteria.

Looking at the microbial armies available to try to counter this yeast attack force, there are some silage microbes that have been proven to produce some strong anti-fungal (kill yeasts and molds) components and which have been demonstrated effective in independent studies.

Propionibacteria, for example, can convert simple sugars and lactic acid to propionic acid and acetic acid, which inhibit the growth of spoilage yeasts and other undesirable microbes. Unfortunately, these bacteria are not very resistant to low pH.

As a result, they tend to be most successfully employed in forage crops with a slow pH decline during ensiling or with a terminal pH of more than 4.2. Research has shown benefits in high-moisture corn and haylages.

Lactobacillus buchneri ( L. buchneri ) is a lactic acid bacterium isolated from aerobically stable corn silage: it was shown to be winning the aerobic stability battle by the controlled production of acetic acid during the storage period.

Significantly, it is the only inoculant active that has been reviewed by the FDA and allowed to claim improved aerobic stability. This is linked to high application rates, i.e., 400,000 CFU per g for silage, 600,000 CFU per g for high-moisture corn (HMC) (compared to the 100,000 CFU per g previously mentioned for homolactic LAB inoculants).

L. buchneri has minimal effect during active fermentation; to overcome this, there are products combining L. buchneri with homolactic bacteria that have been proven in independent trials in a wide range of materials including high-DM haylages (yes, haylages can suffer aerobic instability; see Figure 1 ), corn silages, HMC, earlage, snaplage, small grain silages, etc., to both control the initial ensiling fermentation and keep the feed stable through feeding.

Should I use a different microbial inoculant on hay silage than I do on corn silage?

The main challenge to ensiling haylage crops is to rapidly achieve a low pH. Legumes have lower contents of sugars for fermentation and strong resistance to pH drop because of high concentrations of protein, organic acids and minerals. But haylages can also be prone to aerobic spoilage, as we have seen.

Conversely, corn silage crops have high levels of fermentable carbohydrates and have a low buffering capacity, which has often led to the view that corn can ensile itself.

While this may be true, assuming top-quality management practices, the fermentation can be made more efficient. And certainly corn silages, and other corn-derived preserved feeds, are prone to aerobic spoilage.

So the question is not really one of crop specificity but making sure the products you choose are loaded up with the right microbial armies to overcome the challenges you will face in your silages and haylages, and that they are proven in recognized independent trials.

The takeaways

• A product being presented as crop-specific may turn out to be from a range containing the exact same formulation with different labels on them to make them “crop-specific.”

Regardless of this, the important thing to ask is whether any product you are being offered has been proven capable of coping with the challenges you will face with data from trials carried out by recognized independent researchers. Ask for the data, the proof.

• Always remember, you need to start with top-quality forage crops; you must practice good management and proven inoculants are a key part of that overall program, not a “magic bullet.”

Practice all of the above and you will be sure to produce the best preserved feeds possible given your situation and local conditions. That is one of the keys to profitability. PD

Bob Charley has a Ph.D. in applied microbiology from the University of Strathclyde in Glasgow, Scotland. Renato J. Schmidt has a Ph.D. in animal nutrition from University of Delaware and is employed by Lallemand Animal Nutrition as a forage products specialist.

Bob Charley

Forage Products Manager

Lallemand Animal Nutrition