Dairy producers and nutritionists understand the value of highly digestible forages and their importance in helping drive high milk production in dairy cows. With corn silage becoming more important to dairy rations and the dairy farm enterprise, it is critical to maximize energy from this crop. Highly digestible brown midrib (BMR) corn silage offers one tool to help maximize milk production on the dairy farm.

Dairy producers and nutritionists understand the value of highly digestible forages and their importance in helping drive high milk production in dairy cows. With corn silage becoming more important to dairy rations and the dairy farm enterprise, it is critical to maximize energy from this crop. Highly digestible brown midrib (BMR) corn silage offers one tool to help maximize milk production on the dairy farm.

BMR corn is not new in the world of corn genetics, having been first identified in the early 1900s. One of the key differences between BMR and non-BMR corn plants is the lower amount of lignin produced in the BMR plant. Lower lignin content is strongly associated with higher fiber digestibility of forages.

One of the biggest drawbacks of planting BMR corn hybrids has been reduced forage yields and agronomic stability. Recent breeding efforts have resulted in improved performance, taking away some of the forage yield and agronomic risks.

Lignin and fiber digestibility of corn

Lignin is the chemical component most commonly associated with low fiber digestibility found in forage crops. Lignin has a negative impact on the nutritional availability of plant fiber, and it interferes with the digestion of cell walls by acting as a physical barrier to microbial enzymes. As a result, lignin has a direct impact on digestible energy of the forage.

Lignin also influences the amount of dry matter an animal can consume. Greater amounts of indigestible fiber in a rumen will result in slower passage of fiber through the animal. When this happens, less microbial energy is produced, resulting in lower animal productivity.

Environmental influences: Lignin development

Similar to other plant functions, the development of lignin in corn plants is influenced by growing conditions. Factors that delay plant development will likely reduce lignin development in those plants.

Lignification tends to increase in plants grown under warmer temperatures. This is most likely because lignin-building enzymes are more active at higher temperatures. It may also be a result of the corn plant partitioning more dry matter to highly lignified tissues like stalks.

Soil moisture deficit, low soil nutrients and low light intensity will generally decrease lignification, largely as a function of the changes in plant development and morphology. When soil nutrients are adequate, however, lignin is not influenced by additional fertilization.

Managing BMR corn silage at harvest

Harvest timing of BMR corn hybrids is similar to that of non-BMR hybrids and should be based on whole-plant moisture content of the chopped forage. Depending on the storage structure, whole-plant moisture should target 60 to 68 percent.

Excessive silage moisture may lead to poor fermentation efficiencies and leaching of high-value nutrients. Ensiling forages at low moisture levels will make packing and effective fermentation more difficult.

Plant maturity at harvest is a key driver of corn silage starch content. As in non-BMR hybrids, starch accumulation in BMR hybrids is the result of conversion of plant sugars to starch. This process occurs as corn kernels fill and is complete when plants reach physiological maturity (black layer).

Delaying corn harvest even a few days as the plant is maturing can result in higher starch content in the silage. For healthy plants, advancing maturity usually results in increased starch content without significant reductions in fiber digestibility.

Kernel processing for BMR hybrids

Just as with non-BMR corn silage, kernel processing of BMR hybrids is critical for maximizing the energy availability of the harvested crop. Kernel processing typically increases the rate of ruminal starch digestibility.

Processing corn silage can help maximize the performance of high-producing dairy cows. It also helps reduce overall feed costs, since supplemental grain can likely be reduced.

Shredlage is one of the keys to making high-quality corn silage. This type of processing of corn silage is still new to the forage chopper industry. University researchers are just beginning to study this technology and its influence on starch and fiber digestibility in the dairy animal.

In general, shredlage processors do a very good job of kernel processing. Other kernel processors are also fully capable of reducing kernel-particle size when adjusted properly. In addition to good kernel processing, shredlage processors allow for longer chop length of the stalk, leaves and husk.

Some dairymen are trying shredlage with longer chop length in an effort to increase effective fiber in the diet and to reduce the amount of straw being fed with rations containing BMR hybrids.

Storing and fermenting BMR corn silage

One of the chief benefits of BMR corn silage is its high fiber digestibility. To take full advantage of this benefit, dairy farmers should plan to store their BMR silage in a separate pile, bunker, silo or bag. This allows them to feed high-energy BMR silage to the highest-producing animals. Without isolation, BMR and non-BMR silages will likely be commingled, limiting the benefit of BMR corn silage on your operation.

Air and moisture are the biggest enemies of good fermentation, whether the corn silage is BMR or non-BMR. Proper ensiling practices are critical for avoiding excessive losses during fermentation and feedout. Producers should pack and cover silage quickly to exclude air and reduce fermentation loss (shrink).

Silage density and shrink loss are inversely related. As packing density increases, shrink loss decreases. The goal should be to have a silage density of at least 15 to 16 pounds of dry matter (DM) per cubic foot.

The most efficient silage preservation begins at harvest when a quality inoculant product is applied. It is highly recommended to use a L. buchneri inoculant with the capacity to quickly drop the pH of the ensiled corn and then help prevent heating (aerobic instability) at feedout when the silage is re-exposed to air.

BMR corn silage is higher in value than non-BMR silage and also tends to contain high sugar content at harvest. These factors, along with the fact that dairy farmers who feed BMR corn silage may have two bunker faces open for feeding, means L. buchneri inoculants are especially important with this crop.

Maximizing BMR’s nutritional benefits at feedout

While all animal groups can be fed BMR silages, the greatest benefit and best payback for your BMR seed investment will be with your highest-producing dairy animals and transition cows.

These top-end dairy cows require the highest energy levels from both fiber and grain. Typically, these animals are limited on intake, which is where higher passage rates of BMR corn silage can offer an advantage.

The additional energy in rations using BMR corn silage is the result of higher intake and rumen passage rates. BMR corn silage can be fed at various levels in the dairy cow’s ration. Frequently, higher forage levels are fed to take advantage of the BMR silage.

Your nutritionist’s help is critical to accurately adjust your BMR forage ration. The nutritionist will use dynamic ration-formulation software to make the best use of the highly digestible forages.

A smooth transition to the new-crop corn silage is important for maintaining ration consistency and preventing off-feed or nutritional imbalance problems. Allowing animals to adjust slowly to new feed over a seven-day to 10-day period is always good advice. Additional ration adjustments will need to be made throughout the year to manage changing starch digestibility of the corn silage.

One thing to watch with BMR silage rations is fiber effectiveness. BMR fiber tends to be fragile, and forage particle length can quickly be reduced to unacceptable levels during handling and mixing. Manage the level of effective fiber (scratch) to maintain cud-chewing and an adequately buffered rumen. In some cases, this may require feeding a small amount of straw in the diet.

As BMR silage-containing rations are fed, feed consumption will likely increase compared with feeding non-BMR corn silage, and milk production will also likely increase when managed correctly. Feeding high-forage diets may also improve overall animal health. PD

-

Daniel Wiersma

- Livestock Information Manager

- DuPont Pioneer

- Email Daniel Wiersma

Lignin is a complex polymer within a plant’s cell walls. Lignin provides structural support and facilitates water transport in the actively growing plant. It also plays a role in helping defend the plant against pests and pathogens.

Lignification is first expressed on a cellular level and is regulated by physiological and biochemical activities of the cell. All of these processes are influenced by environmental factors that can affect the extent and impact of lignification.

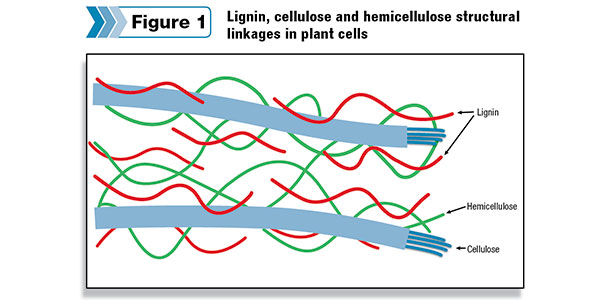

In the cell walls of corn, lignin is chemically cross-linked with cellulose and hemicellulose cell walls through ferulic-acid bridges. This cross-linkage provides rigidity to plants. Through cell replication and expansion, lignin is formed as a normal part of the corn development process.

Scientists have studied the expression of lignin in plants such as corn and alfalfa. Reducing the expression of lignin in plants can occur at various levels.

When lignin expression is strongly reduced, plants fail to develop normally and have collapsed cell walls. However, modest suppression of lignin can lead to normally developed plants while still having reduced levels of lignin.

Today’s BMR corn hybrids are an excellent example of reducing lignin while still maintaining high productivity.