Iodine-based teat dips containing nonylphenol ethoxylates, or NPEs, were once the standard throughout the dairy industry. As possible side effects of NPEs have become known, use has gradually decreased in the U.S. and worldwide. Now a ban by China on the use of this material in milk production products is prompting the component’s final days.

The change will affect major sectors of the U.S. dairy market, though teat dip product suppliers say viable alternatives do exist – at a somewhat increased cost.

“This is a trade issue,” explains Thomas C. Hemling, Ph.D., global manager of research and development for DeLaval Manufacturing. “It’s a change U.S. producers will have to make if they want to continue to export dairy products to China.”

NPEs were once commonly used in commercial and household detergents, primarily degreasers and laundry detergent. They are still used in dairy operations as external surface cleaners, where they do not come in contact with milk.

But their use in teat dips has come under recent scrutiny. Traditionally popular with producers, iodine-based teat dips provide an economical disinfectant and skin conditioner. NPEs have been a key component in that compound, binding the iodine and keeping it in suspension. But unlike external equipment cleaners, NPEs in teat dips can leave residue in milk.

Use has declined over the past several decades since the science began to show NPEs cause disruptions to aquatic life. “The effect mimics estrogen,” says Hemling. In other words, fish take on “feminine” qualities that affect growth and reproduction – and in some cases lead to increased mortality.

Use in household products and detergents was curtailed, and the dairy industry started to back away when it became aware of possible effects on infants and children. “They consume milk as a higher percentage of their weight and diet,” Hemling adds.

Dairy industry product suppliers have responded. NPEs were banned in Europe around 10 years ago, and DeLaval stopped using them in products there. The company has offered NPE-free iodine teat disinfectant products for more than 30 years in the U.S.

Ecolab also began producing non-NPE products – some iodine-based and some not. “We responded to concerns and reformulated products, and conducted lab and field trials, and found them just as effective,” says Stan Palmer, area vice president for Ecolab, Inc. The products are widely accepted by producers, though there do appear to be regional preferences.

Non-iodine, NPE-free products use a variety of active germicides including chlorine dioxide, heptanoic acid, lactic acid and hydrogen peroxide. In many cases, there are advantages to their use. Chlorine dioxide and lactic acid products have unique skin conditioning properties that promote the reduction of hyperkeratosis.

Ecolab now offers more than a dozen NPE-free teat dips, and DeLaval has removed the substance from all of its U.S. marketed dips. Producers will notice some differences in non-NPE iodine-based dips, such as color, viscosity, and potentially, price. They can be more costly. NPE products gained popularity in the first place because they were a cheap option.

China says ‘no’

It’s a cost producers will need to absorb if they want to continue to export nearly 15 percent of U.S. dairy products. China has now placed a ban on imported dairy products containing more than 10 parts per billion (ppb) NPE.

But the ban does not apply to milk domestically produced in China, explains Hemling: “The consumer preference for the imported milk over the domestic product has incited retailers to charge a premium for the imported dairy products, sometimes two to four times the price. The Chinese seem to have taken a position on imported dairy product quality that ensures it remains differentiated from domestic production.”

That’s put pressure on processors to eliminate the additive or have their product rejected.

The pressure rolls back up the supply chain to U.S. suppliers and producers. In some cases, compliance is expected within a short time frame – 60 days or less.

“Dairy processors in Minnesota, California and Texas have already notified their producers to eliminate NPE from their teat dips,” Palmer says. “I expect that this will march across the country from west to east, and in some reasonable time, will take affect all across the country.”

“Some processors have even implemented on-farm inspections,” Hemling says. “It’s easy to detect and deal with NPEs in teat disinfectants. It’s harder in milk.” He says processing companies are asking product companies like DeLaval for information and they, in turn, are increasing sales staff education with training and webinars throughout their dealer network.

Government action?

There are also signs the Environmental Protection Agency may get on board. A proposed EPA rule would designate any use of 15 different NP and NPE agents as “new use” and therefore make them subject to regulatory control under a Significant New Use Rule (SNUR).

Under the SNUR, manufacture of any new product containing these substances would require 90 days notice to the EPA, allowing for study and evaluation of any negative health or environmental effects.

The EPA action is aimed at industrial, not necessarily agricultural, use. The proposed rule specifically cites NPEs used in laundry detergents, engine and battery cleaners, all-purpose cleaners, paints, metal polishers, stain pre-treatment, sealants, paint/varnish strippers, wallpaper removers, hand cleaners, floor strippers, disinfectant/mold inhibitors, concrete cleaners, tile/grout cleaners, degreasers, brush cleaners, tile adhesives and wood finishes.

It also cites studies showing a range of levels of NPs and NPEs has been measured in surface water and sediment in U.S. waters. The Great Lakes, the Ohio River, and lakes in Minnesota have all shown levels above what the EPA considers acceptable for aquatic life, with the highest levels near industrial discharge sites.

Canada has also established a concern level for NPs and NPEs although certain regulated drug products are exempt.

While, technically, the SNUR applies to new industrial uses, it is clear NPE’s days are numbered, even for limited agricultural use.

And that leaves dairy producers with few options according to Hemling: switch to a proven, effective, non-NPE iodine teat dip available on the market today; switch to a currently available non-NPE, non-iodine teat dip; or switch to a new product yet to hit the market.

“Dairymen are creatures of habit and creatures of results, and this is something they will have to wrestle with the next couple of years,” says Palmer, adding his thoughts on their motivation. “The marketplace will take care of the problem much faster than the government will.”

Hemling agrees: “It’s not a regulatory issue – yet. And not likely to become one. The trade situation will dictate NPE use before it comes to that.” PD

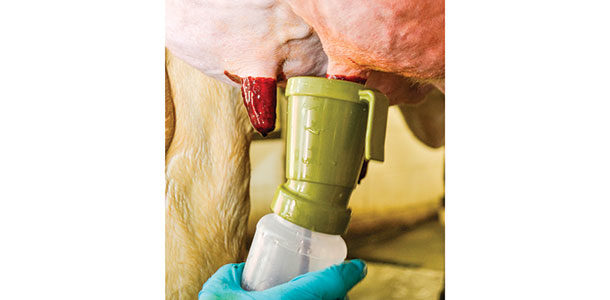

PHOTO

U.S. product supply companies and producers are adjusting to a world without NPEs in teat dips due to a ban by China on the substance. Photo courtesy of DeLaval.

Terri Queck-Matzie is a freelance writer in Fontanelle, Iowa. Learn more at her website.