When I was young, I saw a magazine advertisement about manure spreaders. The catch phrase was that they stood behind all their equipment but the manure spreader. I think about that a lot when I am screening manure.

It’s a dirty job, but if done consistently and routinely, it can open up a world of what is going on inside the cow. This “back-end biology” is used for troubleshooting rumination and fermentation of feed delivered to the cow. What goes in must come out, and this is a way to see how feed is utilized. It is not a perfect science, but, when combined with other troubleshooting tools, it can be invaluable.

For years, we have been taught that there are several different versions of the same ration on the farm – paper ration versus mixed ration versus fed ration versus digested ration. The paper ration is balanced to the second decimal point, and from there it is a matter of how the ration is mixed and fed. Then the real fun begins as rumination and fermentation take over.

This is where the manure screen is a vital tool in the toolbox. When combined with milk components, other solids, de novo fatty acid, fecal starch evaluation and the Penn State particle separator, the manure screener can paint a nice picture of what we don’t see on the paper ration. Manure screening has been used over the last 15 years to benchmark rumination and true ration digestion.

An easy analogy is to relate manure screening to the Penn State particle separator, with one exception – one is going in and the other is coming out. It is a true measure of rumination that goes beyond paper ration, beyond mixed ration and beyond fed ration. It is a reflection of the balance between effective fiber, rate of passage and ration kinetics.

Some consultants use this tool when they see issues arise, some use it on a routine basis to track changes over time and others have never used it. Likely the reason is a lack of concrete interpretations and recent scientific data that ties the results together with the different scenarios. The key thing to remember when using the manure screening tool is that the nutritionist is evaluating diet changes over time for that herd.

Using a manure screening tool

The go-to tool in manure screening is the Nasco digestion analyzer. The digestion analyzer – or as it’s more commonly known, manure screen – is the gold standard for manure screening. Sampling is straightforward and a good part of a group walk-through. Use the scoop or a comparable-sized container and grab a sample in the 500- to 600-gram range from 10 to 12 representative cows.

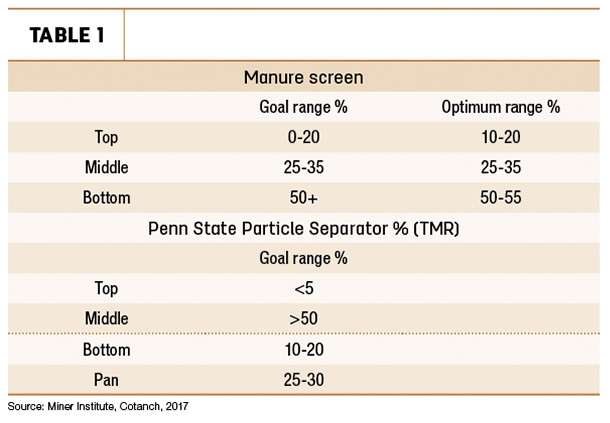

It is best when benchmarking the herd to not take samples on the extremes of the manure consistency spectrum. An important tip is to wring out excess water from the sample residue on each screen, then weigh the amounts. Note the totals and calculate each screen as a percent of the total weight (Table 1).

Oftentimes, when I see a real quality manure screen, the forage fibers will look fine, similar to strands of baler twine. The goal is to have consistency with the manure screen results.

Manure screening resurgence

There are new and exciting ways to use this tool. First, tracking manure screen results over time can help us evaluate rate of passage, grain processing, as well as fiber fermentability by the percentages in the top, middle and bottom screens.

A secondary use is to evaluate forage changes, as well as seasonal changes. How is that highly fermentable forage sample utilized in the cow? Is heat stress and overcrowding affecting rumination to the point where we are losing fiber and starch fermentability?

Other uses are to evaluate rumen fermentation prior to and then after making ration changes. Was the change positive or negative? Then comes the magic of combining manure screen results with herd data and component analytics to match the timeframe.

Top screen interpretation

If we see a higher-than-desired amount of whole or poorly digested fiber particles in the top screen, that is typically a sign of poor rumen synchronization. Mature forages with low-quality fiber that contain high undigestible fiber fractions (high uNDF240) or a lack of sufficient rumen ammonia to feed fiber-digesting bacteria might be probable causes.

Poorly processed on-farm grains, such as dry ground corn with high vitreous starch levels may also be seen in this screen and sometimes the second screen. Correct processing of corn silage, corn meal or adding an exogenous enzyme additive could be considered to help improve rumen synchronization and herd performance. Excessively long bulky fiber particles from recently harvested, non-fermented feed is another scenario that can add fiber to the top screen.

An example is dry, mature and fluffy corn silage harvested after a killing frost. When compared to the Penn State particle shaker box, the top manure screen would correlate to the top and second screens of the Penn State shaker. Top screen percentages between 25% to 40% are typical of herds struggling to generate milk volume.

There is even more that can be seen in manure. In situations with mycotoxins, endotoxins, poor rumen function or acidosis, we can see mucin casts in the top screen. These fibrous, worm-like red materials are remnants of the gut lining that have sloughed off from an improper rumen environment. This can be an excellent early warning sign or a confirmation of issues on farm.

Another common finding in the top screen is gelatinized starch (Figure 1), which is often a sign of hindgut fermentation. This is due to a lack of fiber and starch being digested in the hindgut and is the result of fiber and starch fraction not being fully fermented in the rumen.

Screen two interpretations

Based on experience in using the manure separator, the percentage in the second manure screen has a positive correlation to both milk production and milk components, similar to the Penn State shaker box. Percentages lower than 20% are indicative of fast fermentable diets with higher levels of digestible fiber and non-fibrous carbohydrates.

Milk volume is usually quite good in these herds, but milk butterfat, and sometimes milk protein, can sometimes be lower than desired. The missing percentage of fiber and small starch fractions normally within this screen are shifted to the top and the bottom screens.

Second screen percentages higher than 35% are usually indicative of poor fiber fermentation, whereby rumen pH dropped too fast to stimulate proper rumen conditions for the growth of specific fiber-fermenting bacteria.

Bottom screen interpretation

The bottom manure screen percentage and the bottom pan of the Penn State shaker are highly correlated. Diets heavy in the bottom pan of the shaker box that contain fast fermentable forage fiber, readily degradable starches and non-fibrous carbohydrates are usually higher in percentage in the manure screen.

Herds that achieve between 50% to 60% consistently throughout the year usually generate high milk volumes and have reproduction numbers above the local average. Herd components will depend on the distribution percentage left in the top and middle screens (see Figure 2).

This where knowledge of ration-balancing skills and ingredient fermentation rates (kd rates) really shines through. Specific feed ingredients and technologies such as live yeast and rumen modifiers have been shown to stimulate certain rumen bacteria and improve volatile fatty acid production.

Nutrition for dairy cows has seen many improvements over the years. Yet there are still simple principles to follow, no matter the advancements in ration software, technology, herd analytics and genetics. Oftentimes, the art of feeding cows comes back to our own senses. Back-end biology can help farms troubleshoot their ration as well as dial in profitability.

It’s a dirty job, but we need to do it.